Nylon / PP / HDPE Corrugated Pipe Extrusion Machine

Playlist

3:06

5:08

3:08

3:31

7:22

3:10

2:45

3:27

2:47

2:48

2:08

3:29

2:25

2:25

1:37

8:11

6:55

3:38

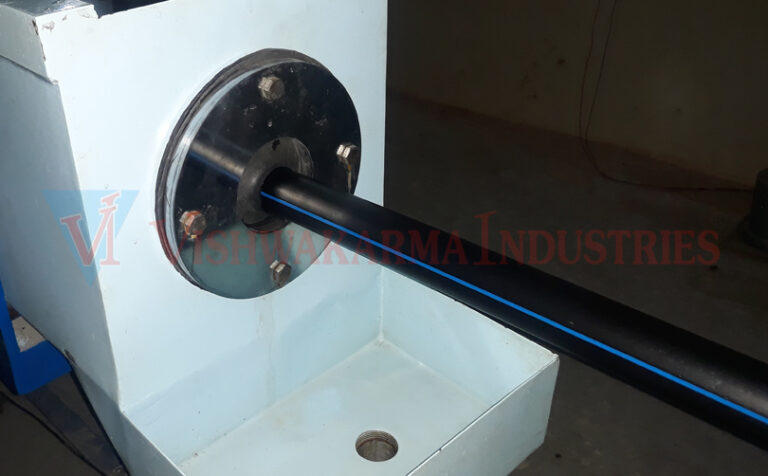

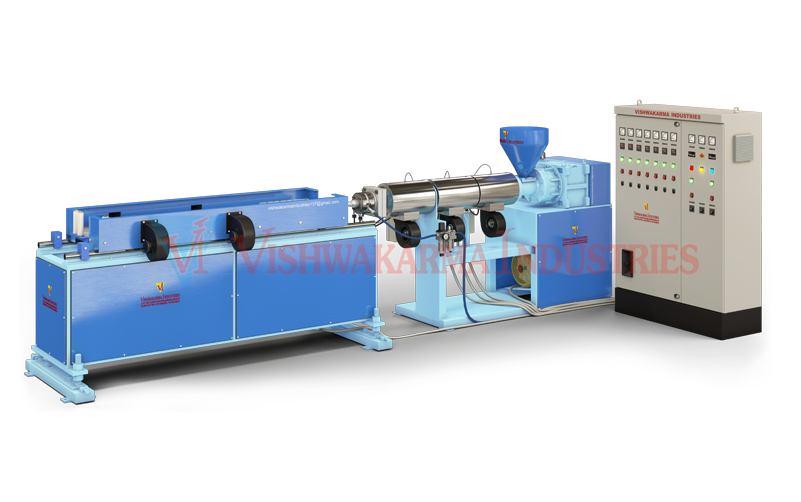

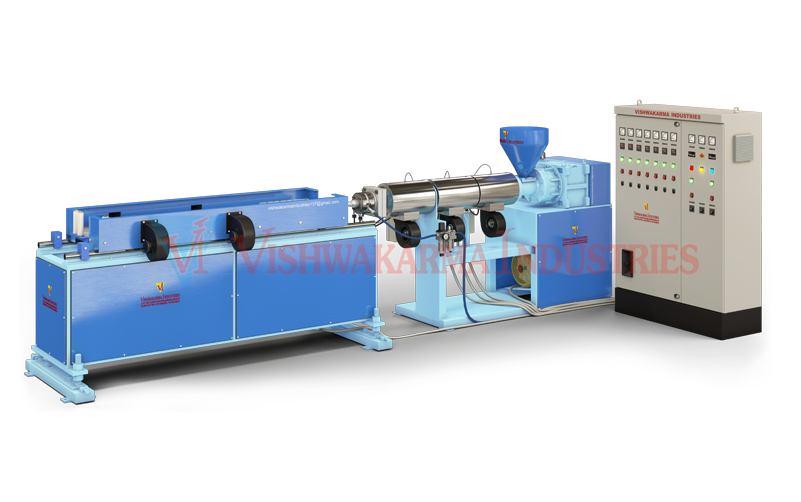

Nylon / PP / HDPE Corrugated Pipe Extrusion Machine High-Speed Corrugated Pipe Extrusion Line Model VI-65

Looking for a reliable and efficient Corrugated Pipe Making Machine? Vishwakarma Industries presents the advanced HDPE / Nylon Corrugated Pipe Extrusion Line, designed for high output, energy efficiency, and precision manufacturing. This machine is ideal for producing single-wall for electrical conduit, Wash Basin, Washing Machine Inlet and Outlet, cable protection, Medical Equipment and fluid management applications.

Founded in 1987 by Mr. Kailash Chand, Vishwakarma Industries is trusted across India and internationally for delivering high-performance machines with excellent after-sales support.

Technical Specifications

The HDPE / Nylon Corrugated Pipe Extrusion Machine is engineered to produce a wide range of high-quality corrugated pipes with superior flexibility, durability, and resistance to chemicals and abrasion. It’s perfect for small to large-scale pipe manufacturing units seeking consistent output with low operational costs.

Models

VI 50

VI 65

Extruder Screw

50 mm

65 mm

Main Motor

10 HP

15 HP

Heating Load

12 HP

15 HP

Berrel Blower Load

0.75 HP

0.75 HP

Take-up

3 HP

3 HP

LD Ratio

25:1

25.:1

Installation Area

30' x 10'

30' x 10'

Pipe Range

8mm to 32mm

10mm to 50mm

Production Approx

5 Kg to 15 Kg

7 Kg to 25 Kg

Advance Features

Our Corrugated Pipe Extrusion Line combines the latest technology with durability and performance.

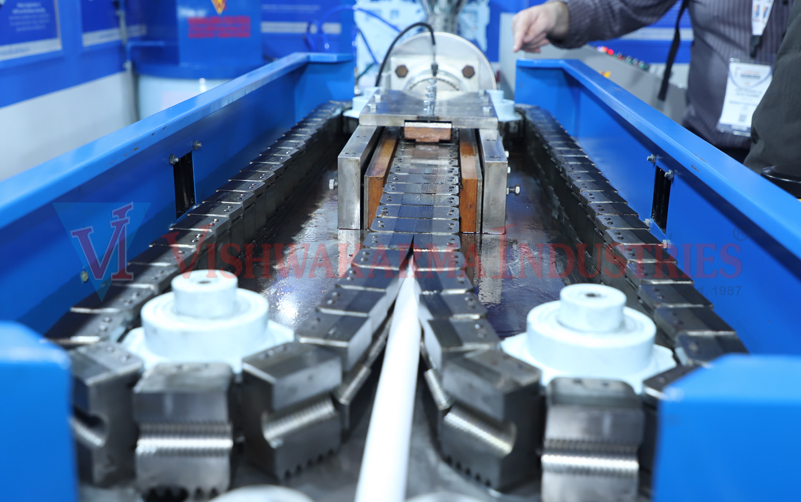

The high-speed extruder ensures uniform melting and smooth flow of HDPE, PPCP, LDP and Nylon material, while the corrugator Molds deliver precise corrugation profiles for enhanced flexibility and strength.

Key Features Include:

✅ High-Speed Extruder with automatic temperature control

✅ Advanced Corrugator with water/air cooling system

✅ User-Friendly Control Panel with PLC integration

✅ Heavy-Duty Machine Frame for continuous industrial operation

✅ High Output with Excellent Pipe Flexibility and Strength

✅ Energy-Efficient Design with low power consumption

✅ Low Noise & Maintenance-Free Operation

Manufacturing Process of Corrugated Pipe

The HDPE / Nylon Corrugated Pipe Making Machine from Vishwakarma Industries follows an efficient and streamlined process to produce flexible, durable, and high-quality corrugated pipes.

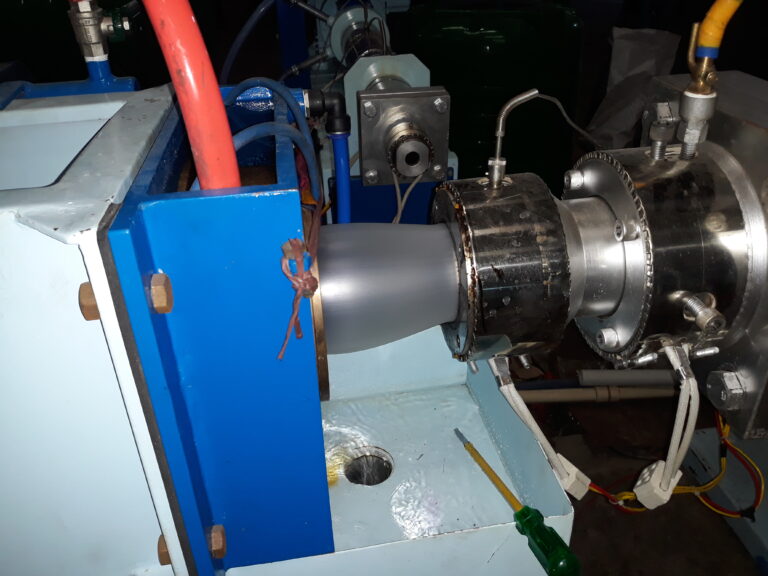

Raw Material Feeding & Extrusion :-

HDPE and LDP or PPCP or Nylon granules are precisely fed into the extruder and melted under controlled temperature.

Corrugation & Shaping :-

The molten material passes through a specially designed die head and is immediately melded into corrugated shape inside the corrugator.

Cooling System :-

Air or water cooling ensures dimensional stability and retains the corrugated structure.

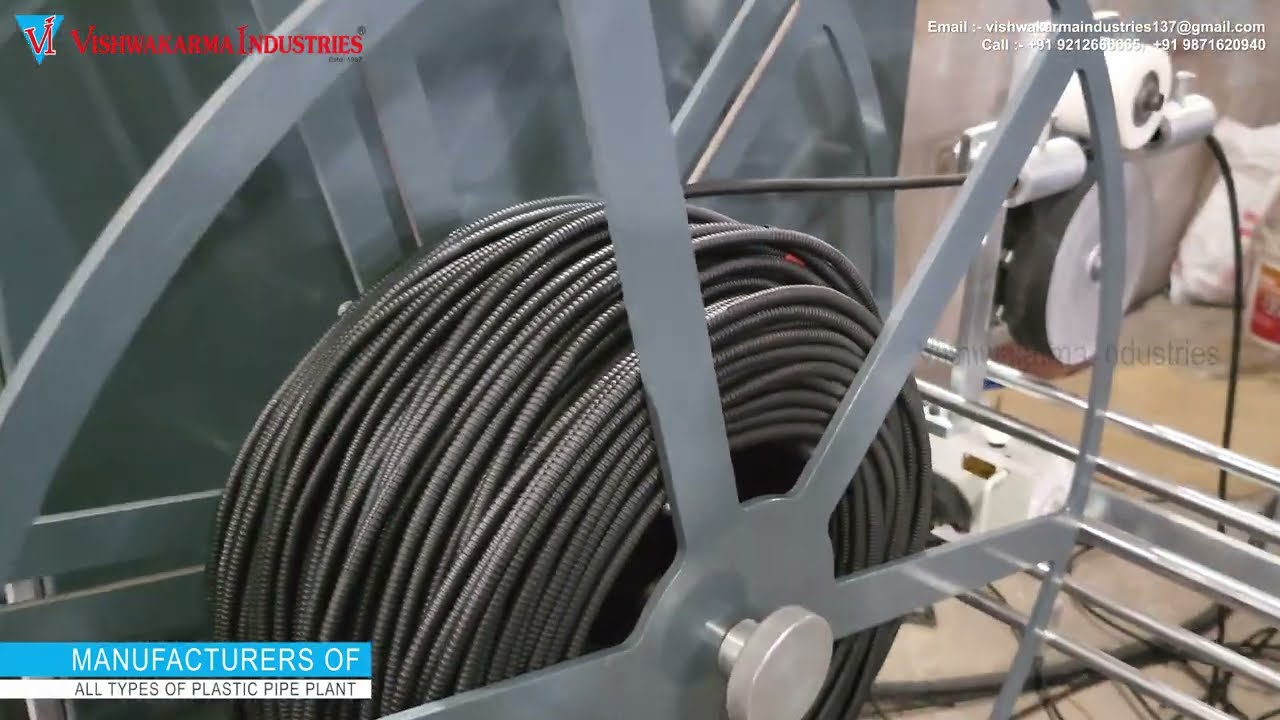

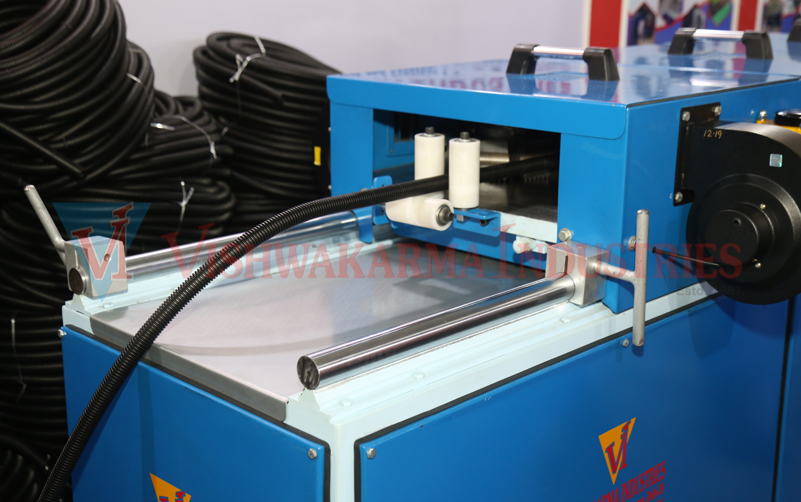

Automatic Roll Winder :-

The automatic roll winder continuously winds the corrugated pipe into rolls up to the preset length. Once the set length is achieved, the machine automatically stops, gives a signal, and allows the operator to remove the finished roll. After roll removal, the system restarts automatically for the next winding cycle. This ensures smooth operation, accurate roll lengths, and easy handling during storage and dispatch.

Control Panel:

The cooled and calibrated pipe is pulled through the extrusion line using a haul-off unit. This unit maintains a consistent tension and speed to avoid any stretching or compression of the pipe. Finally, the pipe is cut to the desired length using an automated cutter. The cut pipes are then collected and inspected for quality before being packaged for distribution.

HDPE / Nylon Corrugated Pipe Utilization

The corrugated pipes produced by this machine are lightweight, flexible, impact-resistant, corrosion-resistant, and easy to install. They provide excellent protection for electrical wiring, HDPE, Nylon, and casing applications, making them ideal for residential, commercial, and industrial projects across India and international markets.

⚡ Electrical Conduit & Cable Protection

Ensures safe, organized routing of electrical wiring with superior insulation and flexibility.

🚗 Automotive Wire Harness & Protection Tubes

Shields vehicle wiring systems from abrasion, vibration, and environmental stress.

🚿 Wash Basin Outlet Pipes

Offers durable, leak-resistant drainage solutions for residential and commercial plumbing.

🧺 Washing Machine Inlet & Outlet Pipes

Provides robust, kink-resistant connections for efficient water flow and long-term reliability.

🩺 Medical Equipment Tubing & Protection

Supports critical healthcare applications with hygienic, flexible, and impact-resistant tubing.

EXPLORE OUR MACHINERY PRODUCTS

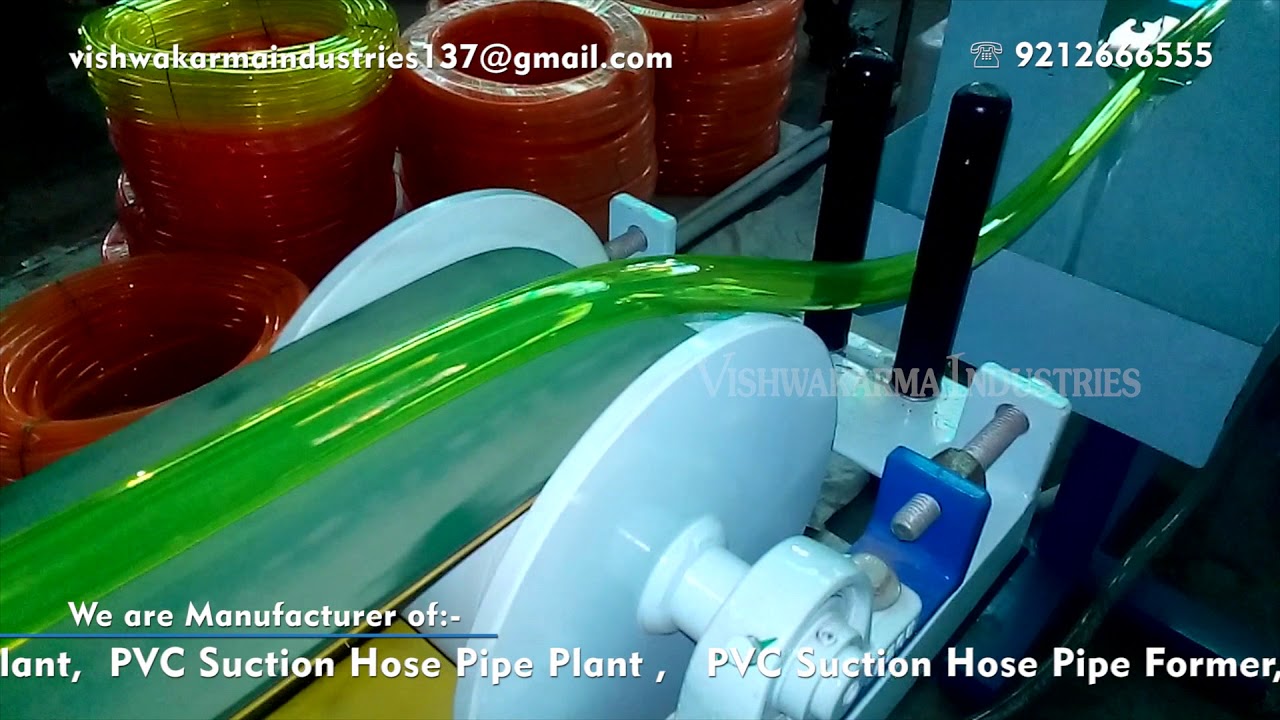

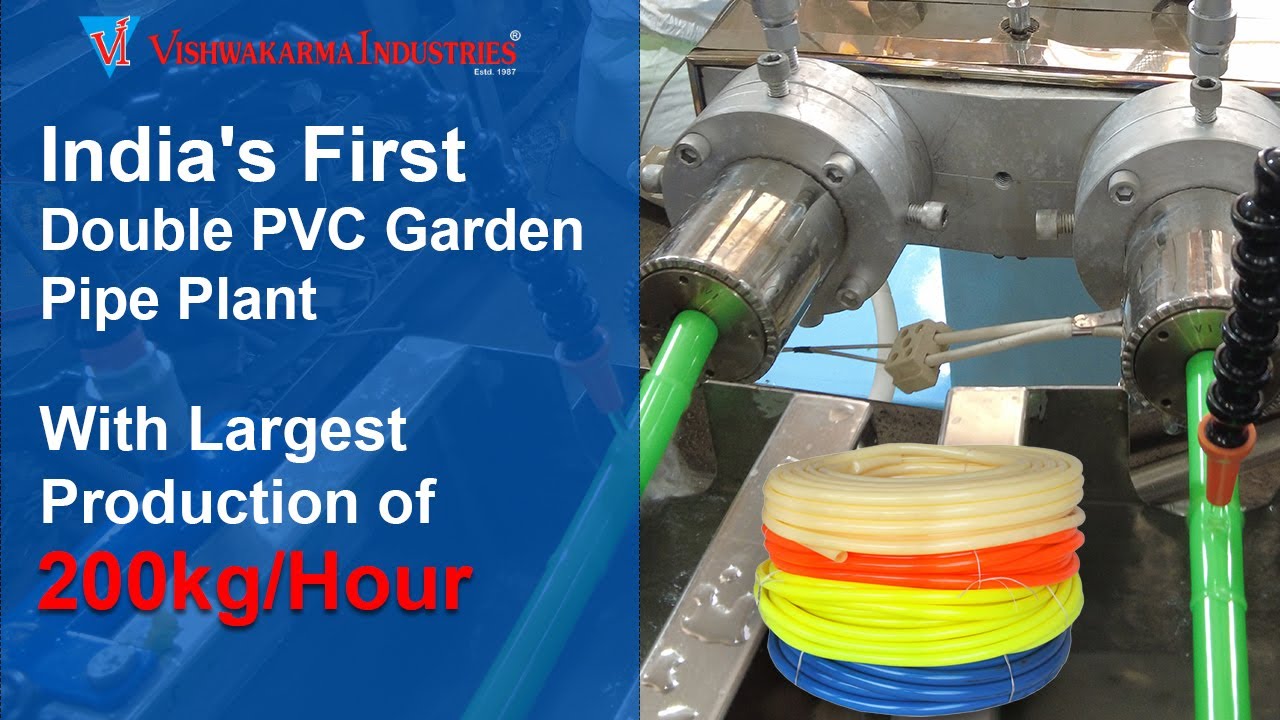

At Vishwakarma Industries, we manufacture and export top-grade machinery used in the plastic pipe industry, such as

Each of our machines is designed for durability, high output, low energy consumption, and minimal maintenance. Whether you’re starting a new unit or expanding capacity, we have a solution that fits your budget and technical needs.