HDPE Pipe Plant (Single, Double, and Triple Layer)

Playlist

2:51

2:50

2:32

2:20

4:17

6:47

7:23

3:08

3:38

2:48

6:55

3:44

5:55

2:25

8:11

6:55

3:38

HDPE Pipe Plant (Single, Double, and Triple Layer)

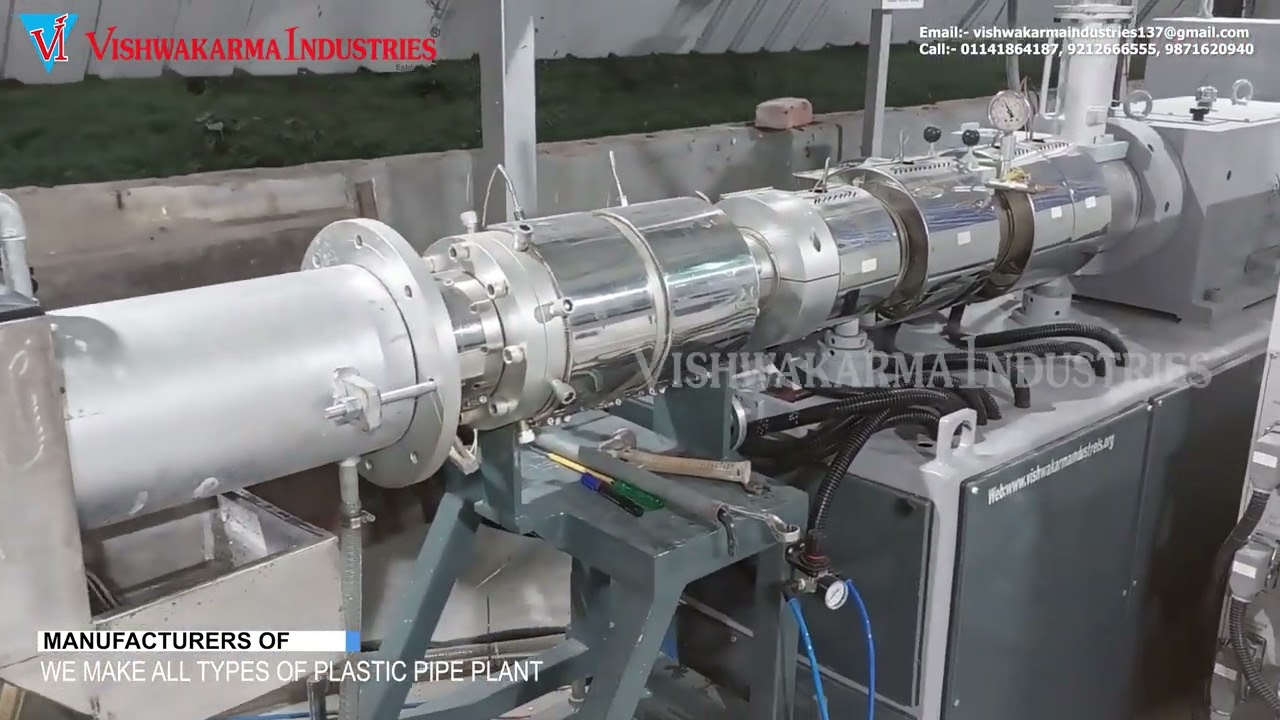

At Vishwakarma Industries, we proudly offer advanced HDPE Pipe Plant solutions designed for the efficient production of single-layer, Dual-layer, and triple-layer HDPE pipes. Engineered with precision and backed by over 35 years of industry experience, our HDPE pipe extrusion lines deliver consistent quality, high output, and energy-efficient performance.

Whether you aim to produce pipes for agriculture, water supply, gas distribution, or industrial applications, our HDPE pipe machines are available in various models to meet your specific size and production requirements.

Technical Specifications

Our HDPE Pipe Plant is engineered for consistent, high-speed production of high-quality pipes, suitable for water supply, gas distribution, cable ducting, and industrial applications. The plant is customizable for single-layer, two-layer, or triple-layer HDPE pipe manufacturing.

- Pipe Diameter Range:- 20 mm to 160 mm (custom sizes available based on model)

- Output Capacity:- 75 kg/hour to 150 kg/hour (model and layer configuration dependent)

- Extruder Type:- High-efficiency single screw extruder + high-torque motor + optional jockey extruders for multi-layer or stripe applications

- Layering:- Optional co-extrusion with jockey extruder for dual-layer, triple-layer, or striped pipes

- Heating Zones:- PID-controlled multi-zone heating system for precise temperature control and uniform material flow

- Cooling System:- Stainless steel vacuum calibration tank + water cooling trough with high-efficiency sprayers for smooth surface finish and dimensional accuracy

- Automation:- Available in semi-automatic and fully automatic versions with optional PLC control for enhanced process management

- Power Consumption:- Designed for energy efficiency, delivering high output at low power usage

👉 Optional Add-ons:- Dual-color stripe unit, online marking/branding system, automatic pipe coiler, or length cutting unit

Models

VI 75

VI 90

VI 45

HI-SPEED

Extruder Screw

75 mm

90 mm

45 mm

Main Motor

20 HP

30 HP

50 HP

Heating Load

15 HP

20 HP

20 HP

Berrel Blower Load

1 HP

1.5 HP

1.5 HP

Jockey Extruder

40 mm

40 mm

50 mm

Motor Load

3 HP

3 HP

10 HP

Heating Load

7 HP

7 HP

7 HP

Vaccum Pump

3 HP

5 HP

5 HP

Take-up

2 HP

2 HP

3 HP

Pipe Cutter

2 HP

3 HP

3 HP

High Speed Mixture

30 HP

30 HP

...........

Water Tank

12" x 12" x 145"

12" x 12" x 250"

12" x 12" x 250"

LD Ratio

28:1

28.:1

30.:1

Installation Area

50' x 20'

80' x 20'

80' x 30'

Pipe Range

1/½" to 2"

1" to 4"

1" to 6"

Production Approx

75 Kg

90 Kg

100 Kg to 150Kg

Advance Features

Our HDPE Pipe Plant is built with cutting-edge technology to deliver superior performance, consistent pipe quality, and maximum productivity for single, two-layer, and triple-layer HDPE pipes. Designed for durability and efficiency, these plants meet the demanding requirements of modern agriculture, infrastructure, gas, and industrial pipe production. Whether you are producing standard HDPE pipes or complex multi-layer pipes, the plant offers reliable operation with minimal maintenance and optimal energy use.

✅ High-Speed Extrusion: Precision single screw extruders and jockey extruders ensure uniform melt flow and smooth pipe walls, even in high-output settings.

✅ Co-Extrusion Layering (for Dual/Three Layers): Jockey extruders provide accurate layering for dual or triple-layer pipes, including UV-resistant, colored, or striped outer layers.

✅ PID Digital Temperature Control: Multi-zone temperature control system for precise heat management, resulting in consistent quality and reduced material waste.

✅ Energy-Efficient Design: Optimized screw and barrel design with low power consumption, reducing operational costs without compromising output.

✅ Stainless Steel Vacuum & Cooling Tanks: For superior calibration, perfect sizing, and smooth, defect-free pipe surfaces.

✅ User-Friendly Operation: Advanced control panels or optional PLC touch screens provide easy monitoring of temperature, speed, and safety alarms.

✅ Custom Pipe Configurations: Suitable for single-layer HDPE pipes or multi-layer HDPE pipes for gas, water, or industrial applications.

✅ Low Noise & Vibration: Engineered for stable operation, making the plant ideal for modern factory environments.

✅ Conclusion

The HDPE Pipe Plant from Vishwakarma Industries offers a complete solution for high-quality HDPE pipe production from single-layer to multi-layer pipes. With advanced technology, robust design, and dedicated service, our extrusion lines help manufacturers achieve maximum productivity at minimal operating cost.

Manufacturing Process of HDPE Pipe (Single, Dual, Triple Layer)

Our HDPE Pipe Plant is designed for the efficient production of single, two-layer, and triple-layer HDPE pipes using advanced co-extrusion and layering technology.

Raw Material Feeding & Mixing:-

HDPE granules and additives (UV stabilizers, masterbatches, etc.) are fed into hoppers and accurately dosed using a gravimetric or volumetric system. This ensures uniform material flow and consistency.

Melting & Main Extrusion:-

The HDPE material is melted and pressurized in the main extruder. The melt flow is uniform, ensuring smooth pipe walls and consistent quality.

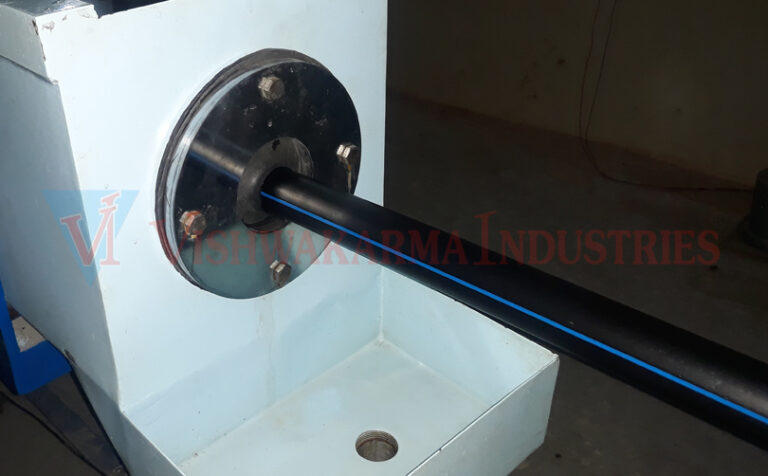

Pipe Sizing & Vacuum Calibration :-

The hot pipe enters the vacuum calibration unit where it achieves its exact outer diameter and wall thickness. This step ensures perfect roundness and dimensional accuracy.

Cooling Unit :-

The pipe passes through stainless steel cooling tanks equipped with high-pressure water sprayers and recirculating pumps. The cooling unit stabilizes the pipe and prevents deformation, ensuring a smooth surface finish.

Haul-off & Cutting / Coiling / Take-Up :-

The finished pipe is uniformly pulled by a precision haul-off unit. It is then cut to desired lengths or coiled (for small-diameter pipes) using a manual or automatic winder.

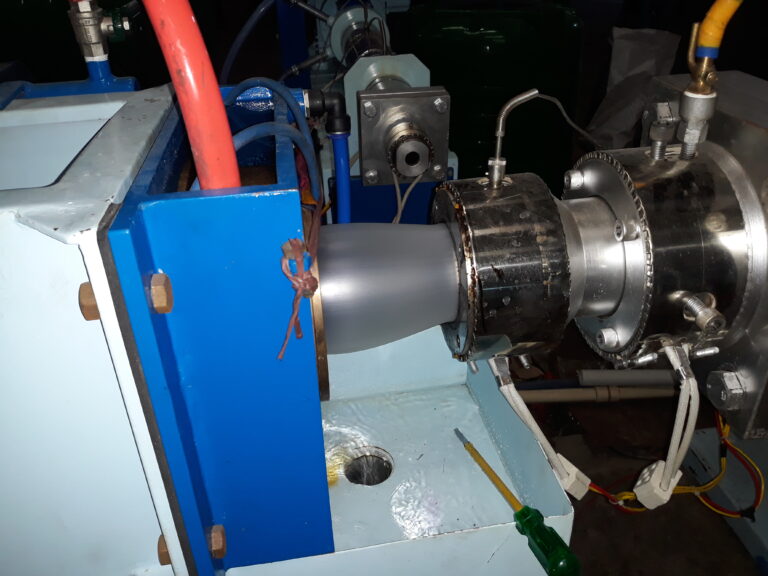

Jockey Extruder for Layering (Dual/Three Layer Models) :-

In Dual-layer and triple-layer models, jockey extruders are used alongside the main extruder to apply outer and/or inner layers.

These jockey extruders enable:

• Co-extrusion of different HDPE grades for inner, middle, and outer layers

• Addition of colored or UV-protective outer layers

• Enhanced adhesion between layers for durable, high-performance pipes

• Customization for dual-color or striped pipes as per application

The jockey extruder works in perfect sync with the main extruder to produce seamless, multi-layer pipes with precise wall thickness control.

Control Panel:

The cooled and calibrated pipe is pulled through the extrusion line using a haul-off unit. This unit maintains a consistent tension and speed to avoid any stretching or compression of the pipe. Finally, the pipe is cut to the desired length using an automated cutter. The cut pipes are then collected and inspected for quality before being packaged for distribution.

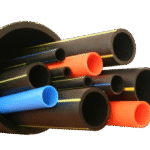

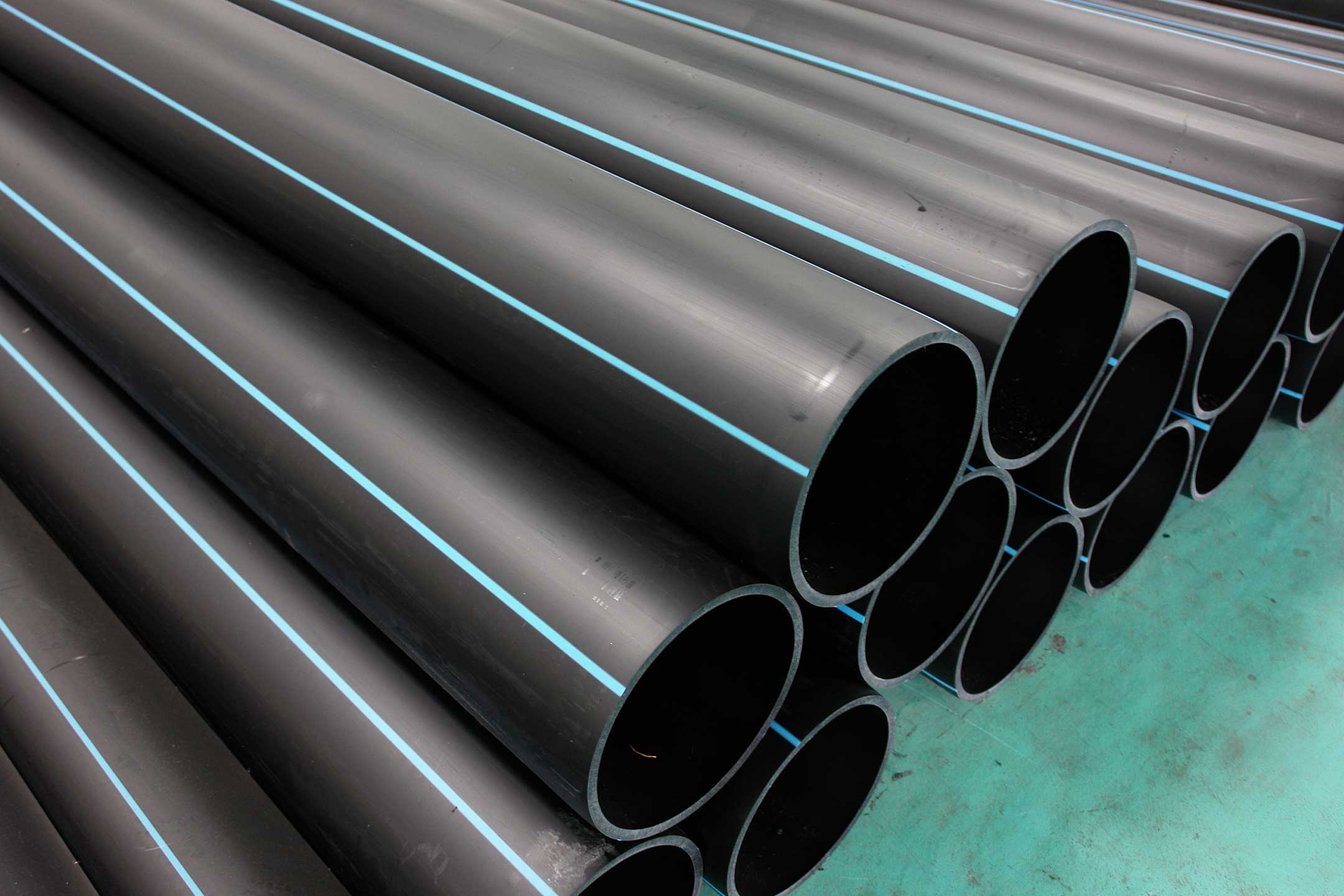

Applications of HDPE Pipes

HDPE pipes are trusted across industries for their strength, flexibility, and resistance to corrosion. Thanks to advanced extrusion technology, they serve a wide range of critical applications

• 🚜 Agricultural Irrigation – Reliable water flow for fields, farms, and plantations

• 🚰 Drinking Water Supply – Safe and hygienic transport of potable water

• ⚡ Underground Cable Ducting – Secure housing for electrical and communication cables

• 🏭 Industrial Effluent Lines – Efficient discharge of chemical and wastewater from factories

• 🔥 Gas Distribution – Safe conveyance of natural gas and LPG

• 🌾 Sprinkler Systems – Uniform water distribution for crop irrigation

From rural farms to urban infrastructure, HDPE pipes deliver performance where it matters most.

EXPLORE OUR MACHINERY PRODUCTS

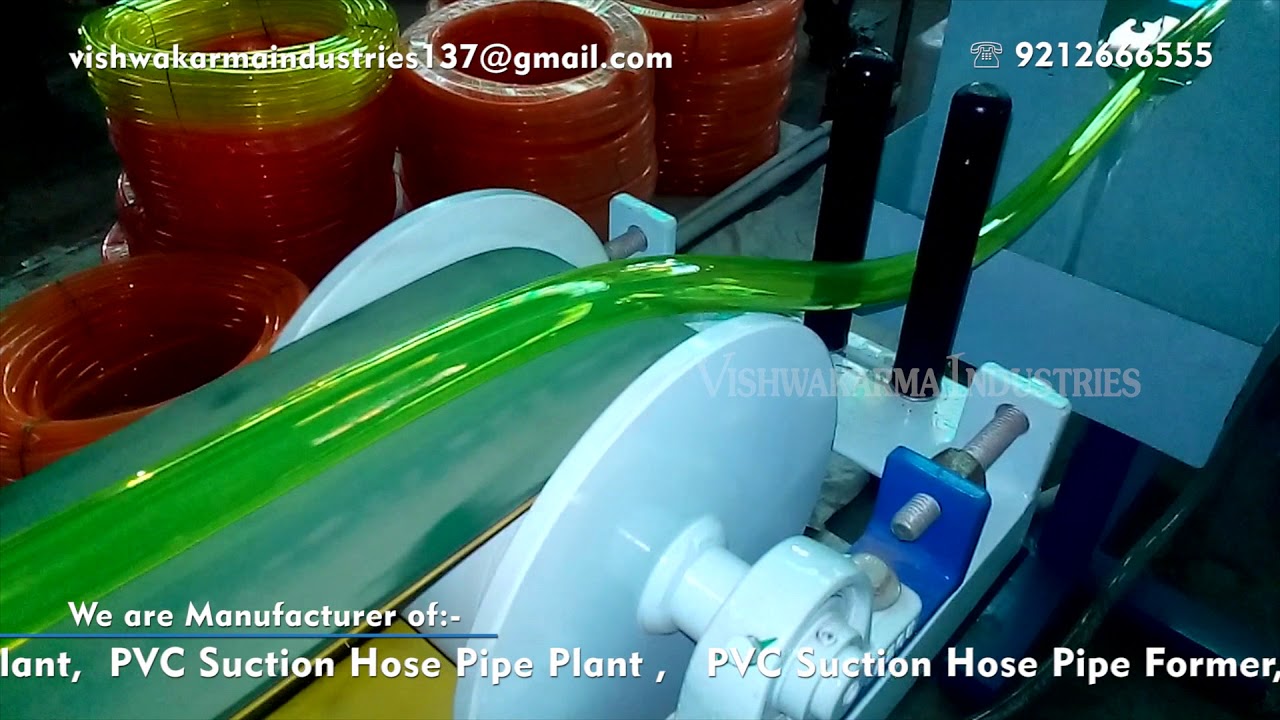

At Vishwakarma Industries, we manufacture and export top-grade machinery used in the plastic pipe industry, such as

Each of our machines is designed for durability, high output, low energy consumption, and minimal maintenance. Whether you’re starting a new unit or expanding capacity, we have a solution that fits your budget and technical needs.