PVC Braided Hose Pipe Plant

Playlist

3:11

2:44

3:44

3:11

7:06

2:37

5:04

6:33

2:13

4:16

6:55

3:38

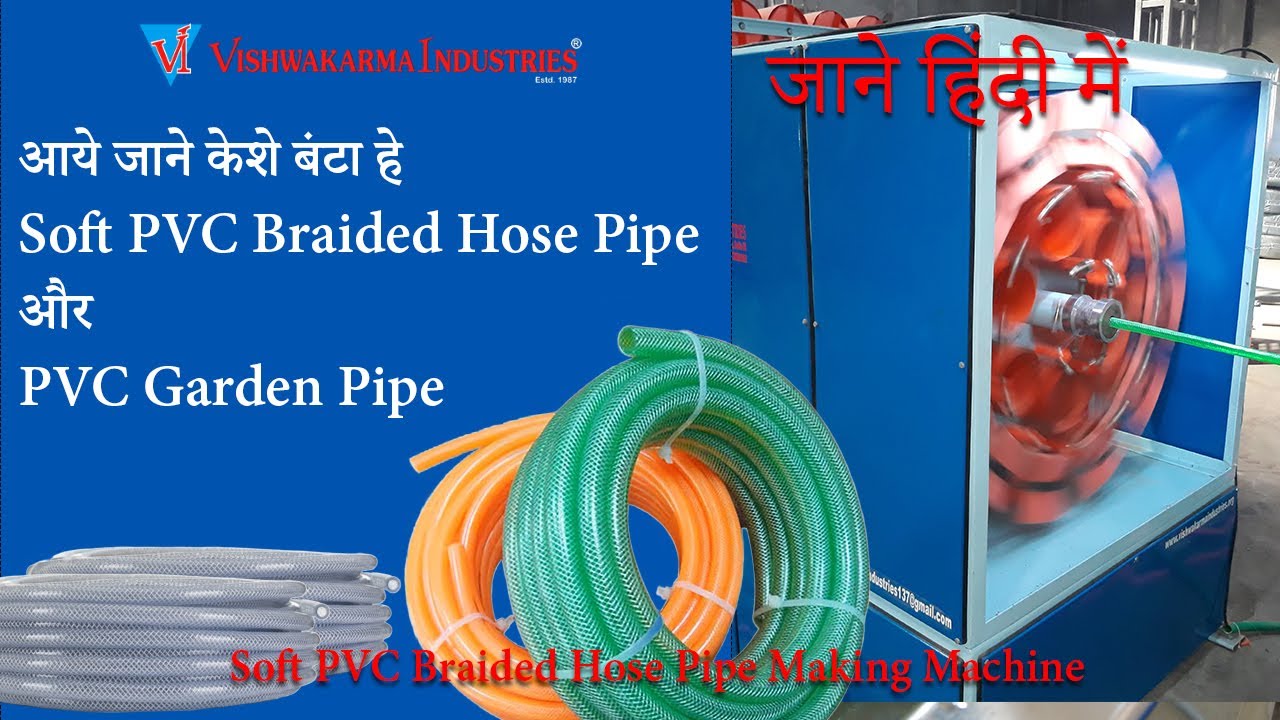

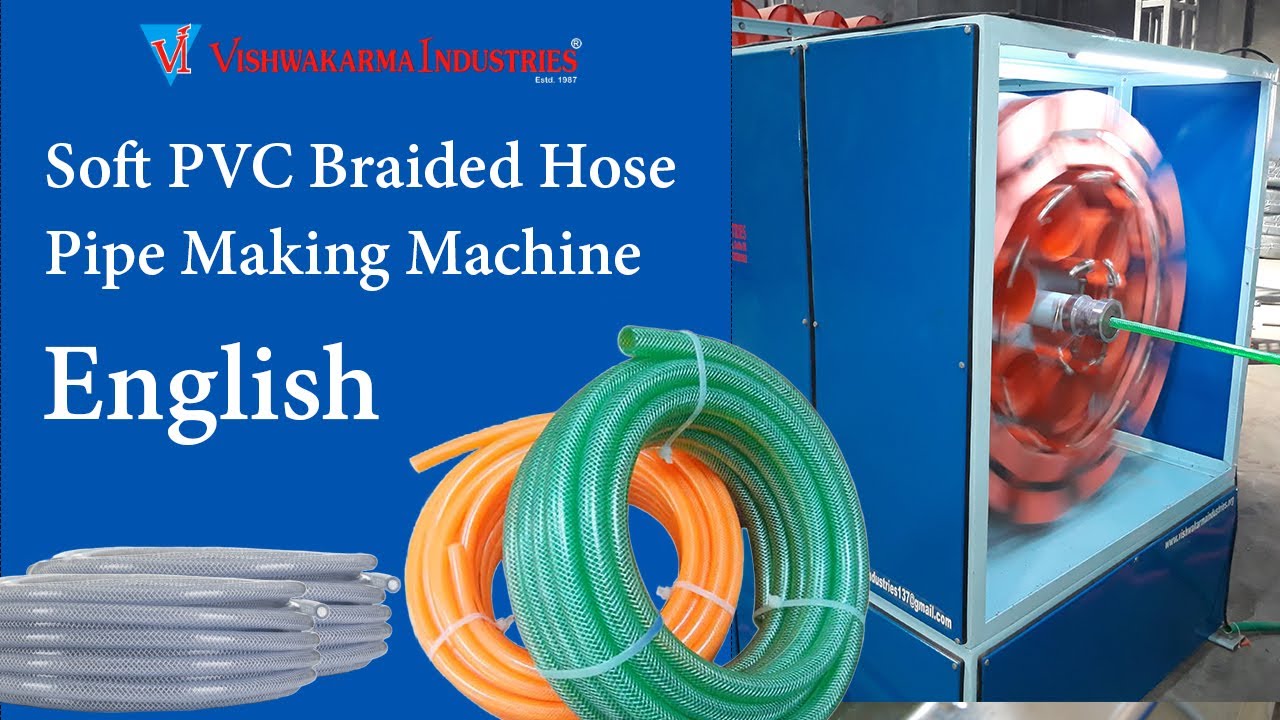

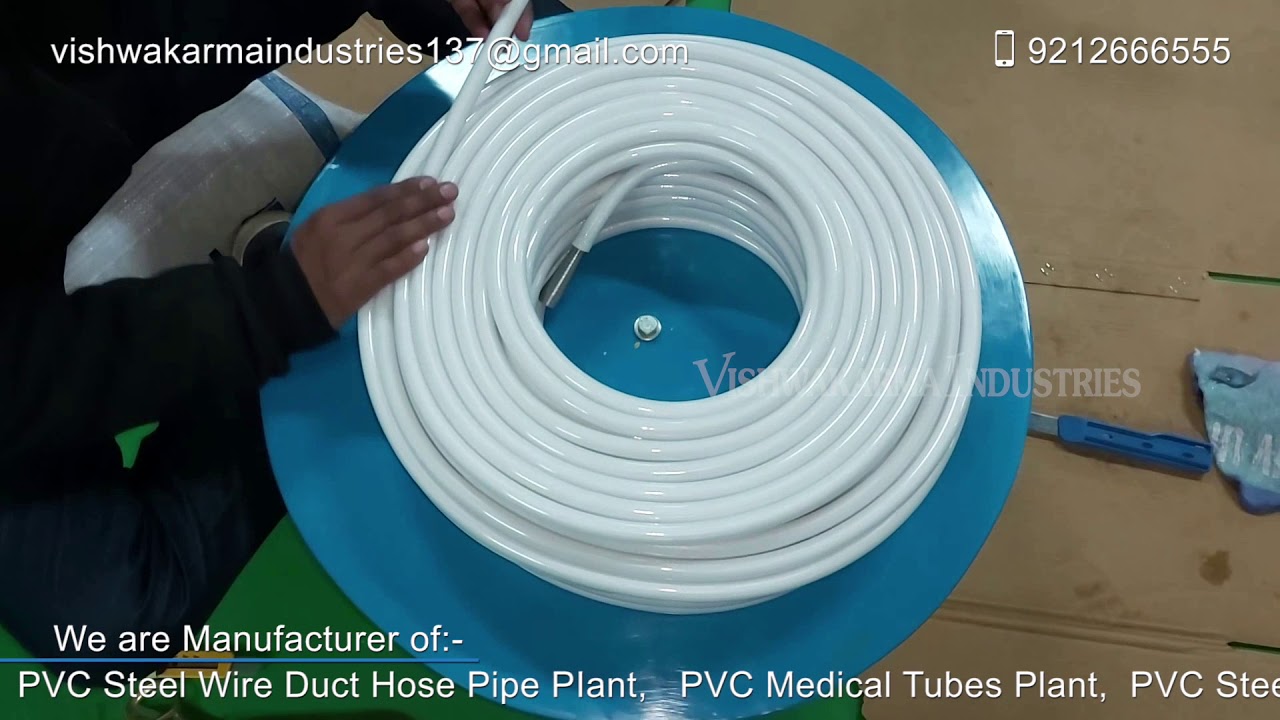

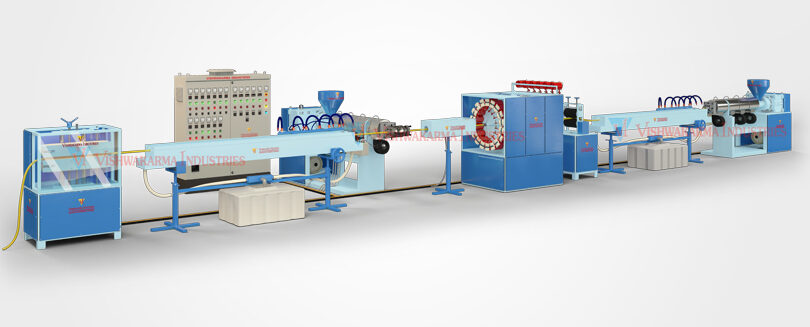

Soft PVC Braided Hose Pipe Making Machine

Vishwakarma Industries, a trusted name in pipe machinery manufacturing since 1987, proudly presents its advanced Soft PVC Braided Hose Pipe Making Machine — your key to producing durable, flexible, and high-pressure PVC braided hoses with ease and efficiency.

👉 Based in Delhi, Vishwakarma Industries has empowered hundreds of successful pipe manufacturing units across India and abroad with its high-performance and low-maintenance machines.

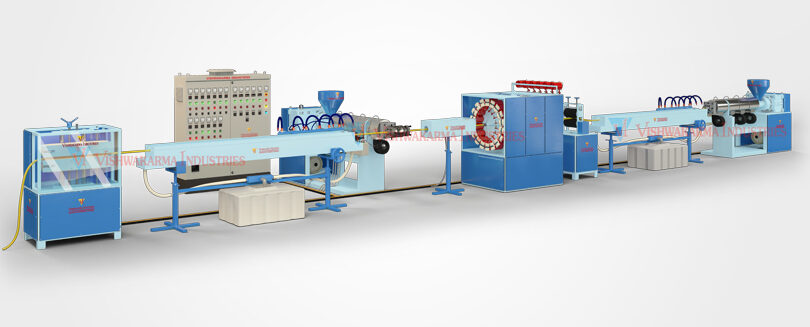

Technical Specifications

The Soft PVC Braided Hose Pipe Making Machine is designed to produce high-quality braided pipes with superior strength and flexibility. Ideal for small to large-scale PVC braided hose pipe manufacturing plants, this machine ensures consistent output and smooth operation.

It supports a pipe diameter range of 6mm to 50mm, with an output capacity of 80–110 kg/hour, depending on the model. The machine is equipped with a single screw extruder, PID-controlled heating zones, and a stainless steel cooling tank for efficient processing. Available in both semi-automatic and fully automatic versions, it meets the diverse needs of pipe manufacturers across India and abroad.

This machine is compatible with soft PVC Braided Hose pipe formulations and can be configured with optional accessories like color stripe units and pipe winders.

Models

VI 75 X 75

Extruder Screw

75mm, 75mm

Main Motor

20 HP, 20 HP

Heating Load

15 HP, 15HP

Berrel Blower Load

2 HP

Braiding Machine

3 HP

Heating Chamber Load

5 HP

Take-up

2 HP

Delivery Take-up

1 HP

High Speed Mixture

30 HP

Water Tank- 2 set

10”x12”x135”

LD Ratio

25:1, 25:1

Installation Area

60’ x 25’

Pipe Range

5mm to 50mm

Production Approx

110 Kg

Advance Features

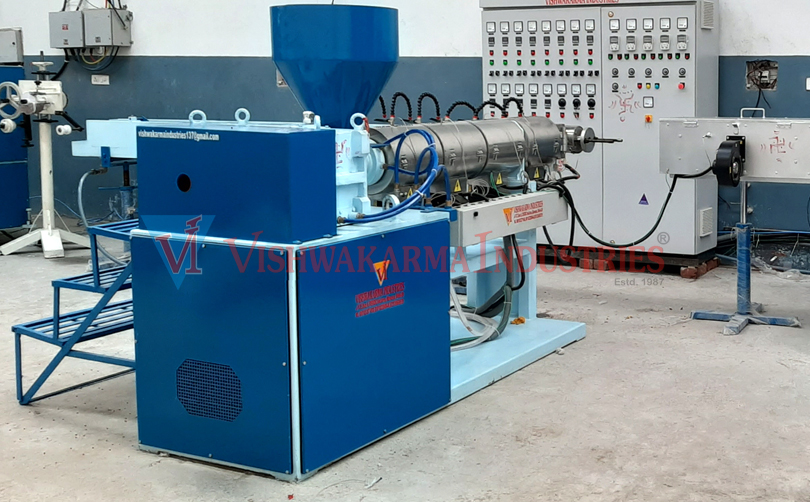

Our Soft PVC Braided Hose Pipe Making Machine incorporates the latest plastic extrusion and braiding technology to deliver reliable performance, easy maintenance, and superior output. Designed for manufacturers aiming for a cost-effective, energy-efficient solution for producing high-pressure flexible PVC braided hoses, this machine is the perfect choice for modern pipe manufacturing units.

The machine features a high-speed single screw extruder that ensures uniform melting and smooth flow of the soft PVC material. The PID digital temperature control system provides precise heat management across multiple zones, guaranteeing consistent braided pipe quality.

The stainless steel cooling tank not only strengthens the braided pipe through uniform cooling but also offers corrosion-free durability, which is a significant advantage for long-term, trouble-free operation.

Key Features Include:

- ✔️ User-Friendly: Easy-to-operate control panel with temperature display

- ✔️ Durable: Heavy-duty structure for 24×7 industrial operations

- ✔️ PID Digital Temperature Controller for stable extrusion performance

- ✔️ High Performance for consistent and efficient pipe production

- ✔️ Eco-Friendly: Designed to reduce environmental impact with sustainable materials.

- ✔️ Low Power Consumption, helping reduce your operational costs

- ✔️ Noise- and Vibration-Free Operation, ideal for indoor factory setup

- ✔️ Automation Options: From semi-auto to fully automatic line

These features make it the best machine for PVC Braided pipe manufacturing in India, combining performance, durability, and affordability.

Manufacturing Process of Soft PVC Braided Pipe

The Soft PVC Braided Pipe Making Machine from Vishwakarma Industries Delhi follows a highly efficient and streamlined manufacturing process designed to produce flexible, durable, and high-quality Braided pipes. The process ensures minimal material wastage and maximum production speed, making it suitable for PVC pipe manufacturing units in India and abroad.

Raw Material Mixing :-

The process begins with the precise mixing of soft PVC granules, plasticizers, stabilizers, lubricants, and color masterbatches. This mixture is thoroughly blended using high-speed mixers to ensure uniformity and consistency in the pipe’s quality and color. Proper raw material preparation is critical for smooth extrusion and long-lasting pipe flexibility.

Melting and Extruding :-

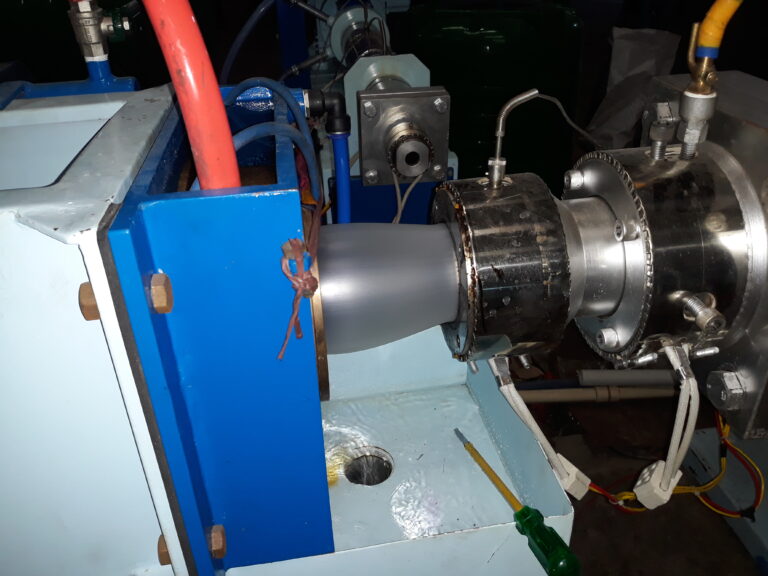

The blended PVC material is fed into the single screw extruder where it is melted uniformly. With PID temperature-controlled heating zones, the soft PVC compound is gradually heated and pushed through the screw and barrel to maintain flow consistency. This is one of the most crucial steps in the PVC pipe extrusion process.

Sizing and Shaping :-

The molten PVC is passed through a specially designed pipe die head, which shapes the pipe into its desired diameter and wall thickness. Immediately after shaping, the pipe enters the sizing sleeve and vacuum calibration unit to ensure accurate dimensions and surface finish.

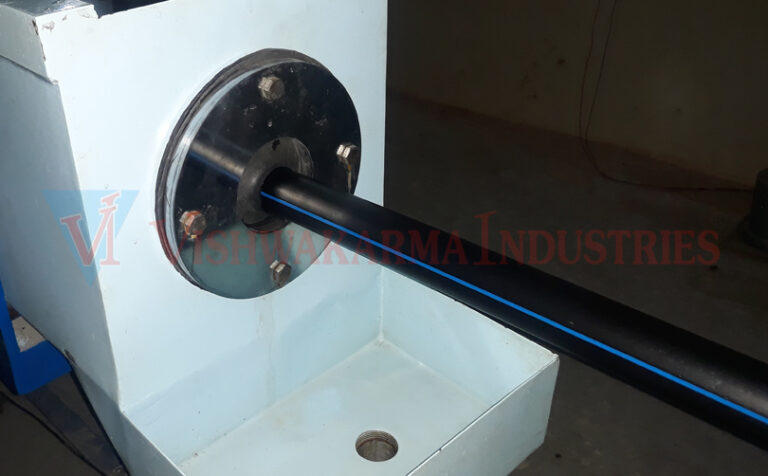

Initial Pipe Cooling System :-

The hot, shaped pipe is passed through a stainless-steel water-cooling tank to solidify and retain its dimensions. Proper cooling prevents pipe deformation and improves flexibility. The cooling system is equipped with water sprayers and a recirculating pump for efficient thermal management.

Braiding Unit :-

The formed PVC hose enters the automatic high-speed braiding machine where polyester / nylon / synthetic yarn is braided over the outer surface. This layer significantly enhances the hose’s pressure resistance, strength, and durability. The braiding unit operates at synchronized speed to maintain uniform braid tension and pattern across the entire hose length.

Extruder for Coating :-

After braiding, a Extruder applies an outer PVC coating over the braided layer. This coating protects the braid, improves aesthetics, and provides UV and chemical resistance. The coating ensures that the braided hose is suitable for heavy-duty and high-pressure applications.

Final Pipe Cooling System :-

The braided and coated hose passes through an enhanced stainless steel water cooling tank. This cooling system ensures that the hose solidifies properly, retains its dimensions, and achieves excellent flexibility without deformation. The system includes water sprayers, a recirculation pump, and an optional chiller unit for precise temperature management.

Haul-Off Unit :-

The haul-off or traction unit pulls the pipe uniformly from the extruder. With adjustable speed controls, it maintains constant pulling tension and ensures the pipe surface is smooth without stretches or deformations. This unit is essential for synchronized operation with the cutting or winding system.

Cutting or Winding :-

Finally, the braided hose is either cut into set lengths by an automatic cutter or wound onto coils using a pipe winder — ready for packaging and dispatch.

Control Panel :-

The entire system is operated through a user-friendly control panel that integrates speed settings, temperature controls, and safety alarms. It allows operators to monitor and adjust key process parameters for consistent pipe output and reduced downtime. Optional PLC-based touch panel upgrades are also available for automation.

Utilization & Applications

The Soft PVC Braided Hose Pipes produced by this machine are widely used across various domestic, commercial, and industrial sectors due to their flexibility, durability, and high-pressure resistance.

The pipes produced are flexible, durable, UV-resistant, and easy to install, making them suitable for a wide range of domestic and commercial uses.

🌱 Agriculture & Irrigation

- Water supply lines for irrigation and sprinkler systems

- Pesticide and fertilizer spray hoses

🚗 Automobile & Garage Uses

- Car washing pipes

- Pneumatic air lines

🏭 Industrial Applications

- Air compressor hoses

- Gas welding and cutting equipment hoses

- Chemical and solvent transfer lines

🏠 Domestic & Utility Uses

- Domestic water supply connections

- Washing machine inlet hoses

- General cleaning and utility piping

💧 Construction Sites & Workshops

- Water supply for curing and cleaning

- High-pressure air and fluid supply lines

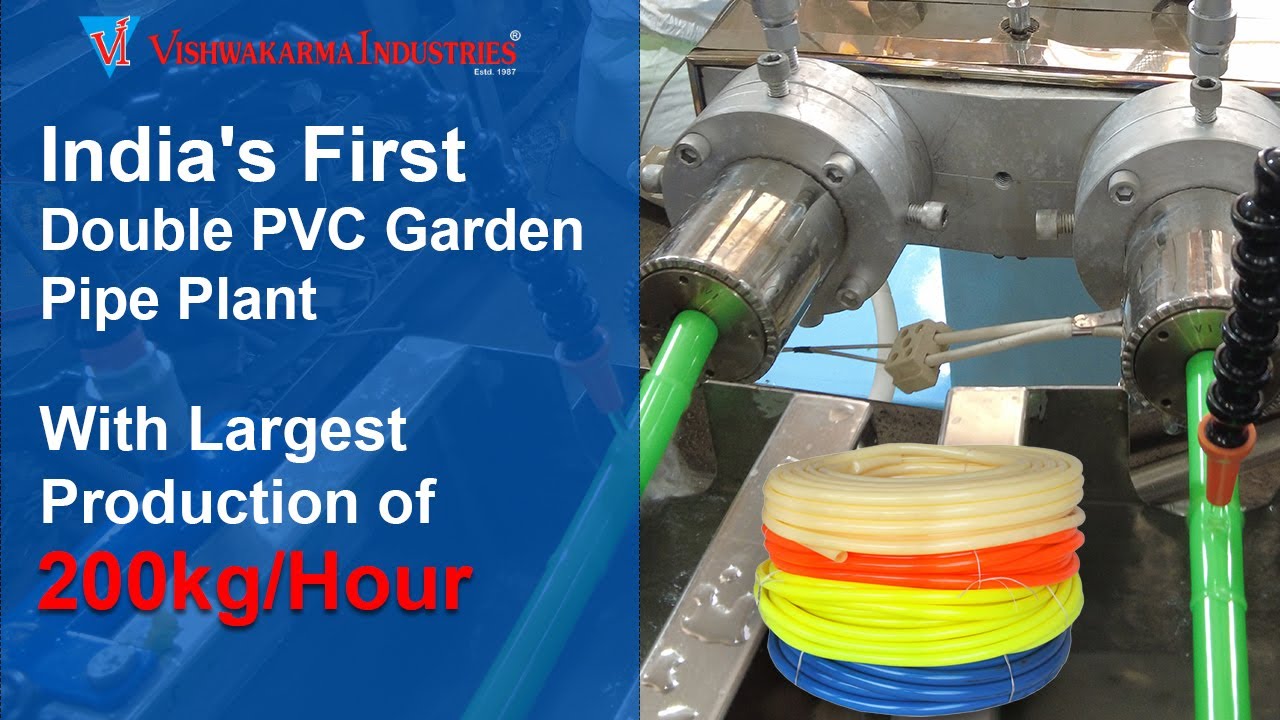

EXPLORE OUR MACHINERY PRODUCTS

At Vishwakarma Industries, we manufacture and export top-grade machinery used in the plastic pipe industry, such as

Each of our machines is designed for durability, high output, low energy consumption, and minimal maintenance. Whether you’re starting a new unit or expanding capacity, we have a solution that fits your budget and technical needs.