PVC Dual Garden Pipe Making Machine

Playlist

4:31

4:22

2:07

2:17

3:11

4:08

1:41

3:08

2:36

2:48

2:08

3:29

2:25

2:25

1:37

8:11

6:55

3:38

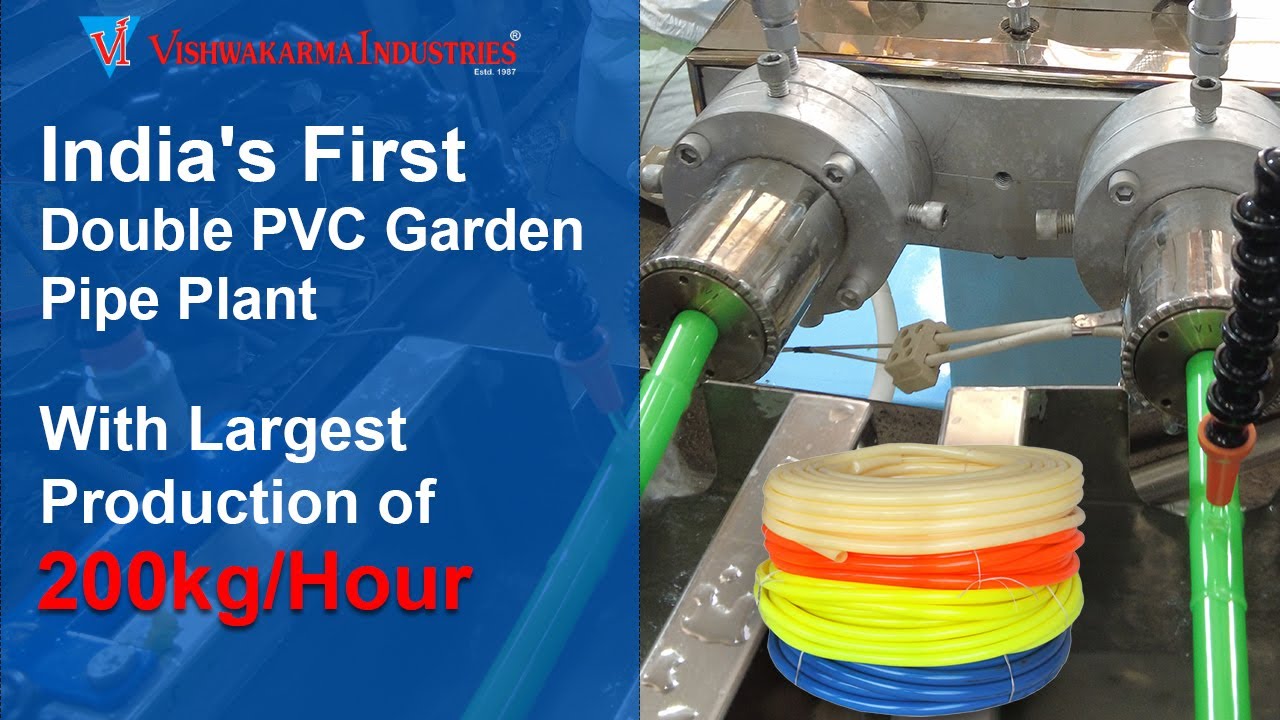

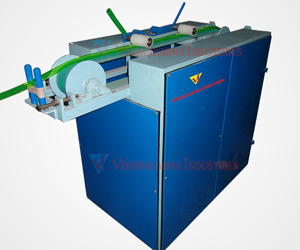

Soft PVC Dual (One Time Two Pipe ) Garden Pipe Making Machine – Model VI-100

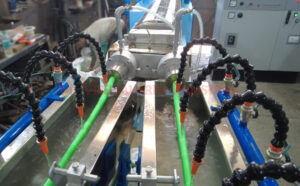

Introducing the Soft PVC Dual (One Time Two Pipe) Garden Pipe Making Machine – Model VI-100 from Vishwakarma Industries. This high-speed machine is designed to produce two flexible PVC garden pipes at the same time. It is a smart choice for entrepreneurs and industries who want to increase output and reduce production time.

Vishwakarma Industries, based in Delhi, India, is a trusted name in PVC pipe machinery. Founded in 1987 by Mr. Kailash Chand, the company is known for making reliable, high-performance extrusion machines. It also offers strong after-sales support across India and abroad.

Technical Specifications

Soft PVC Dual Garden Pipe Making Machine Model: VI-100 By Vishwakarma Industries, Delhi

The VI-100 model is built to produce two soft PVC garden pipes at the same time. It offers high flexibility, strong durability, and fast output. This machine is perfect for medium to large-scale pipe manufacturers who want consistent dual-pipe production with maximum efficiency.

✅ Key Specifications

Pipe Size Range: 12mm to 50mm (both pipes produced together)

Output Capacity: 100–200 kg/hour (combined for both pipes)

Extrusion System: Single screw extruders (main + jockey or shared)

Heating Zones: Multi-zone PID temperature control for stable heating

Cooling System: Dual stainless steel tanks or shared long tank with two lanes

Automation Options: Available in semi-automatic and fully automatic versions

Models

VI 100

Extruder Screw

100 mm

Main Motor

25 HP

Heating Load

20 HP

Berrel Blower Load

1.5 HP

Jockey Extruder

40 mm

Motor Load

3 HP

Heating Load

7 HP

Take-up

1 HP + 1 HP

High Speed Mixture

30 HP

Water Tank

10" x 10" x 195" + 10" x 10" x 195"

LD Ratio

25.:1

Installation Area

50' x 50'

Pipe Range

10mm to 40mm

Production Approx

200 Kg

Advance Features

Soft PVC Dual Garden Pipe Making Machine Model: VI-100 By Vishwakarma Industries, Delhi

The VI-100 model uses advanced plastic extrusion technology. It is built for reliable performance, easy maintenance, and high-speed output. This machine produces two soft PVC garden pipes at the same time, helping manufacturers increase productivity and profits.

🔍 Industry Trends & Innovations

♻️ Eco-Friendly Additives Manufacturers are now using safer plasticizers and additives. These help reduce the environmental impact of PVC pipes. They also improve recyclability and may support future biodegradability.

⚙️ Advanced Extrusion Technology Modern machines use computer controls, automatic quality checks, and energy-saving heaters. These upgrades improve speed, accuracy, and efficiency.

🌱 Biodegradable PVC Researchers are working on PVC materials that can break down naturally. This helps reduce long-term waste and supports eco-friendly goals.

📡 Smart Pipes Some PVC pipes now include sensors. These can detect leaks, track flow, and send real-time data. This helps with faster maintenance and better system control.

🔬 High-Performance Blends New blends of PVC and other materials are being tested. These improve pipe strength, flexibility, and resistance to heat and chemicals.

✅ Conclusion

The PVC Transparent Garden Pipe Plant by Vishwakarma Industries shows how far extrusion technology has come. It produces strong, clear garden pipes used in farming, vehicles, medical setups, and food handling.

With a focus on innovation and sustainability, Vishwakarma Industries continues to lead in PVC pipe machinery. The future of PVC pipes looks bright—with better performance, more uses, and less impact on the environment.

PVC Soft Pipe Manufacturing Process

Making PVC transparent garden pipes requires many important steps. Each step helps improve the pipe’s quality.

Raw Material Preparation:

The process starts with preparing the raw materials. High-quality PVC resin is the main material used to make the pipes. This resin is chosen carefully to ensure strong and reliable pipes. Additives like plasticizers, stabilizers, lubricants, and pigments are mixed with the resin. These additives improve flexibility, heat resistance, and color.

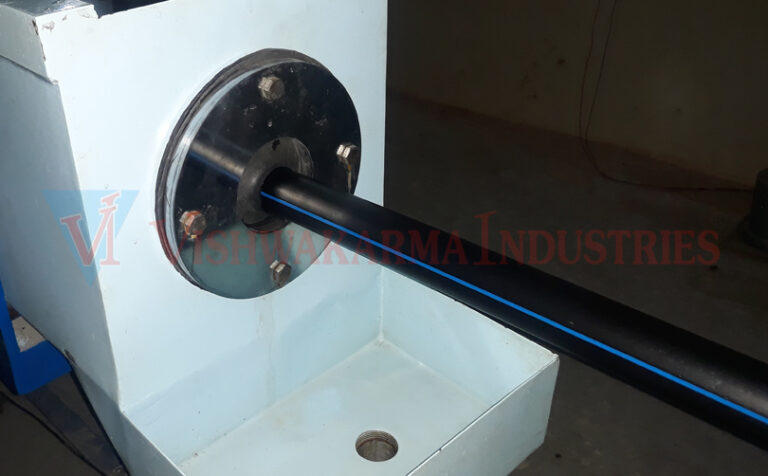

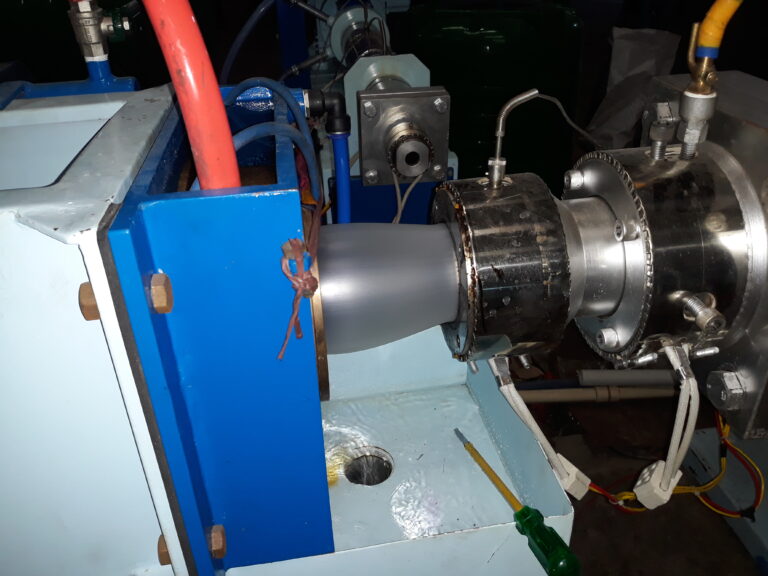

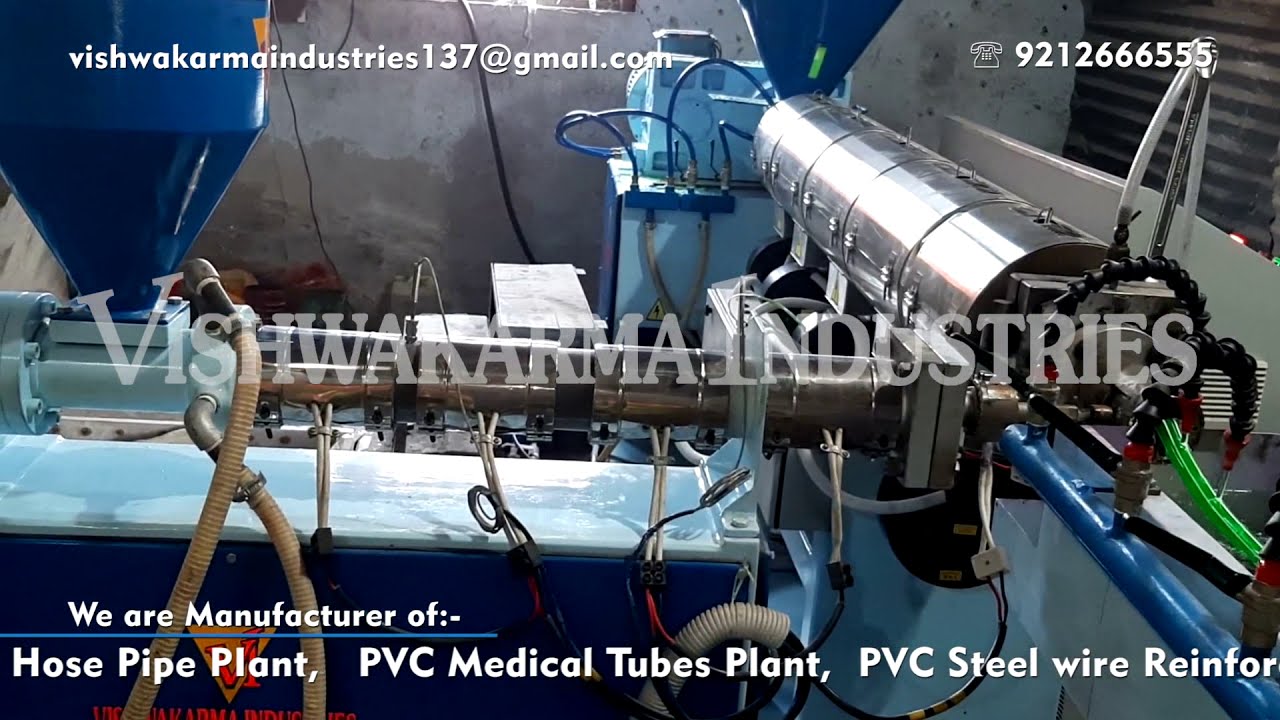

Extruder:

The mixed raw material goes into an extruder. This machine melts and shapes the material into a continuous pipe. The extruder has a barrel and a screw system. The screw pushes the material forward while heating it. As it moves, the material melts, mixes, and becomes smooth and uniform.

Shaping and Sizing:

The molten PVC is then passed through a die, a tool that shapes the material into a specific profile. In this case, the die shapes the PVC into a hollow tube, which will become the garden pipe. The shaped pipe is then cooled and sized using a vacuum sizing unit. This unit ensures that the pipe maintains its dimensions and shape as it cools down.

Pipe Cooling System :

After extrusion, the pipe is cooled using water baths or cooling chambers. This step helps the pipe become solid and keeps its shape. Once cooled, the pipe moves through a calibration unit. This unit checks the pipe’s size and makes sure it meets the required standards.

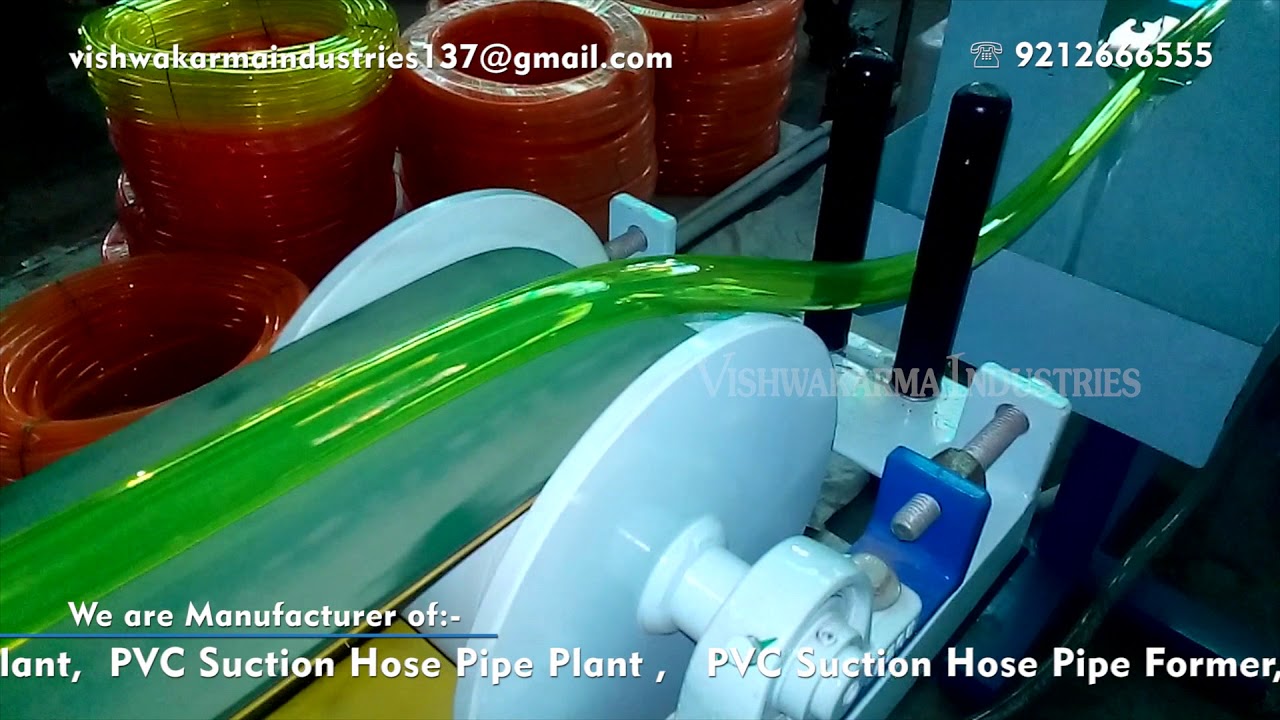

Patta Take-Up:

After cooling and calibration, the pipe is pulled forward by a haul-off unit. This unit keeps the speed and tension steady to prevent stretching or shrinking. Next, an automatic cutter trims the pipe to the required length. The finished pipes are then collected, checked for quality, and packed for delivery.

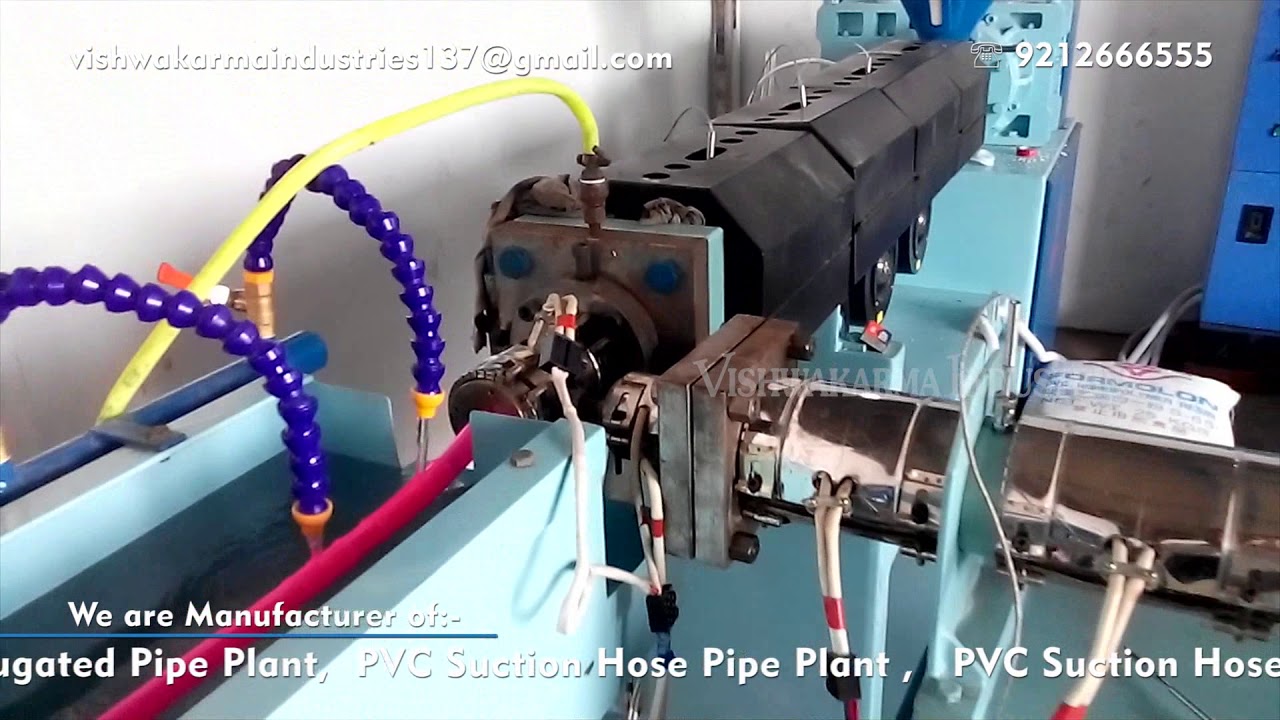

Jockey Extruder:

After cooling and calibration, the pipe is pulled forward by a haul-off unit. This unit keeps the speed and tension steady. It prevents the pipe from stretching or shrinking. Next, an automatic cutter trims the pipe to the required length. The finished pipes are then collected, checked for quality, and packed for delivery.

Control Panel:

After cooling and sizing, the pipe is pulled forward by a haul-off unit. This unit keeps the speed and tension steady. It prevents the pipe from stretching or shrinking. Next, an automatic cutter trims the pipe to the required length. The finished pipes are then collected, checked for quality, and packed for delivery.

PVC Soft Pipe Utilization

PVC Transparent Garden Pipes are used in many industries. Their flexibility and strength make them suitable for a wide range of tasks. Here are some key areas where these pipes are commonly used:

💧 Water Supply

Used for watering gardens, lawns, and farms. Their flexibility makes them easy to handle. Transparency helps monitor water flow. Ideal for irrigation systems.

🚗 Automobiles

Used for fluid transfer like coolant lines, AC systems, and washer tubes. They resist heat and chemicals, making them perfect for engine areas.

🌾 Agriculture

Used in hydroponics for nutrient delivery and water circulation. They resist UV rays and chemicals, making them suitable for outdoor use.

🥤 Food & Chemical Handling

Used to transfer liquids, syrups, and chemicals. Non-toxic and easy to clean. Meets hygiene standards in food and beverage industries.

🌊 Water Suction & Discharge

Used to drain pools, ponds, and tanks. Strong and abrasion-resistant. Suitable for heavy-duty water movement.

💊 Pharmaceuticals

Used to transfer fluids and chemicals during production. Transparency allows easy flow monitoring. Helps meet strict quality standards.

EXPLORE OUR MACHINERY PRODUCTS

At Vishwakarma Industries, we manufacture and export top-grade machinery used in the plastic pipe industry, such as

Each of our machines is designed for durability, high output, low energy consumption, and minimal maintenance. Whether you’re starting a new unit or expanding capacity, we have a solution that fits your budget and technical needs.