PVC Foam Garden Hose Pipe Plant

Playlist

4:31

4:22

2:07

2:17

3:11

4:08

1:41

3:08

2:36

2:48

2:08

3:29

2:25

2:25

1:37

8:11

6:55

3:38

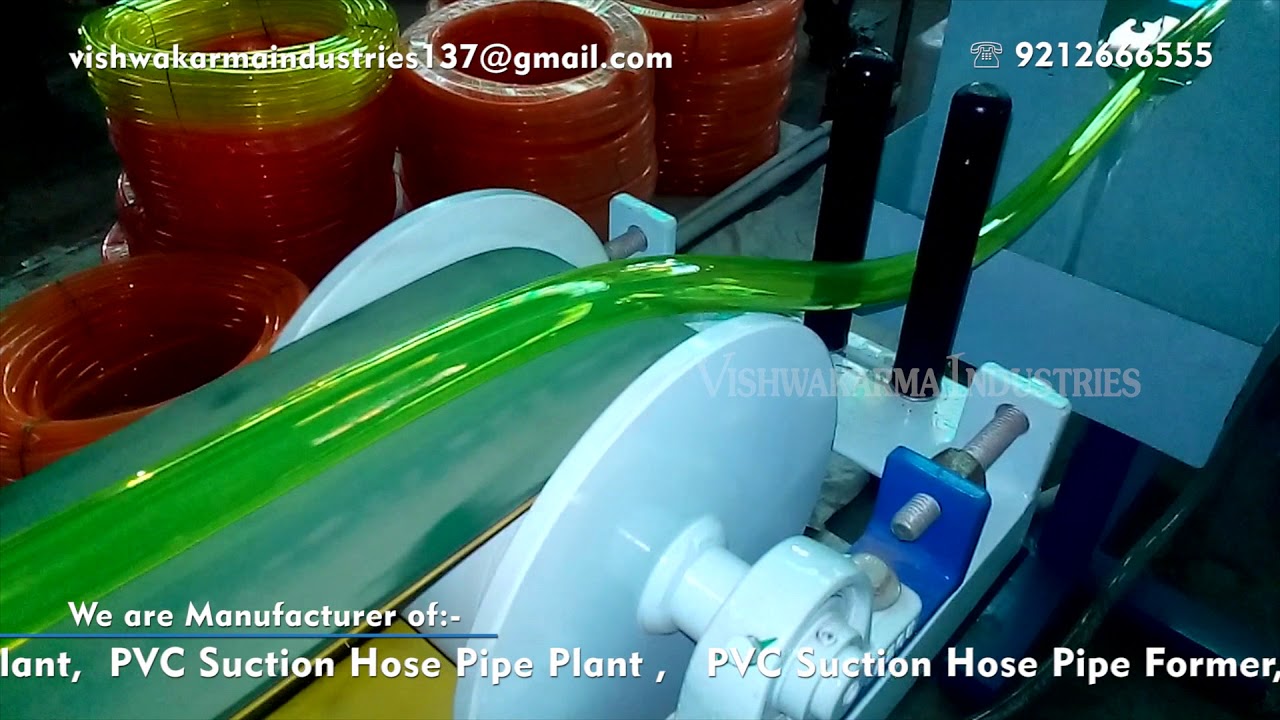

PVC Foam Garden Hose Pipe Plant,

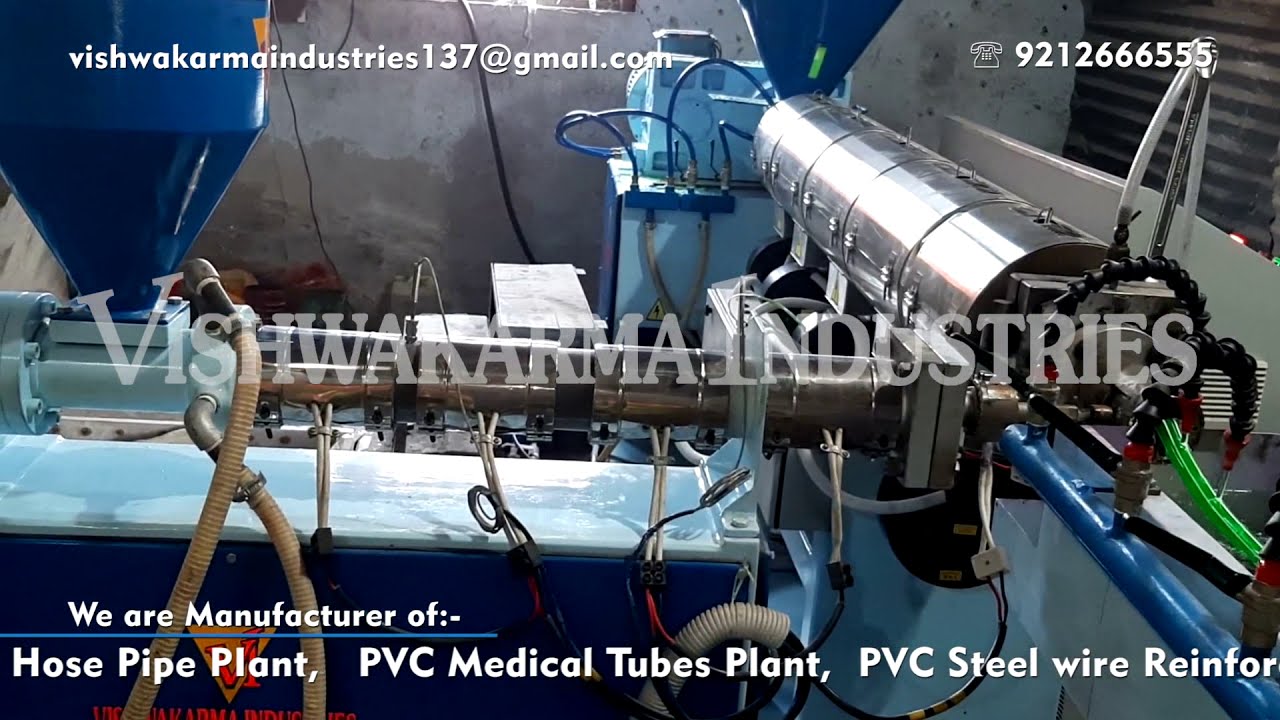

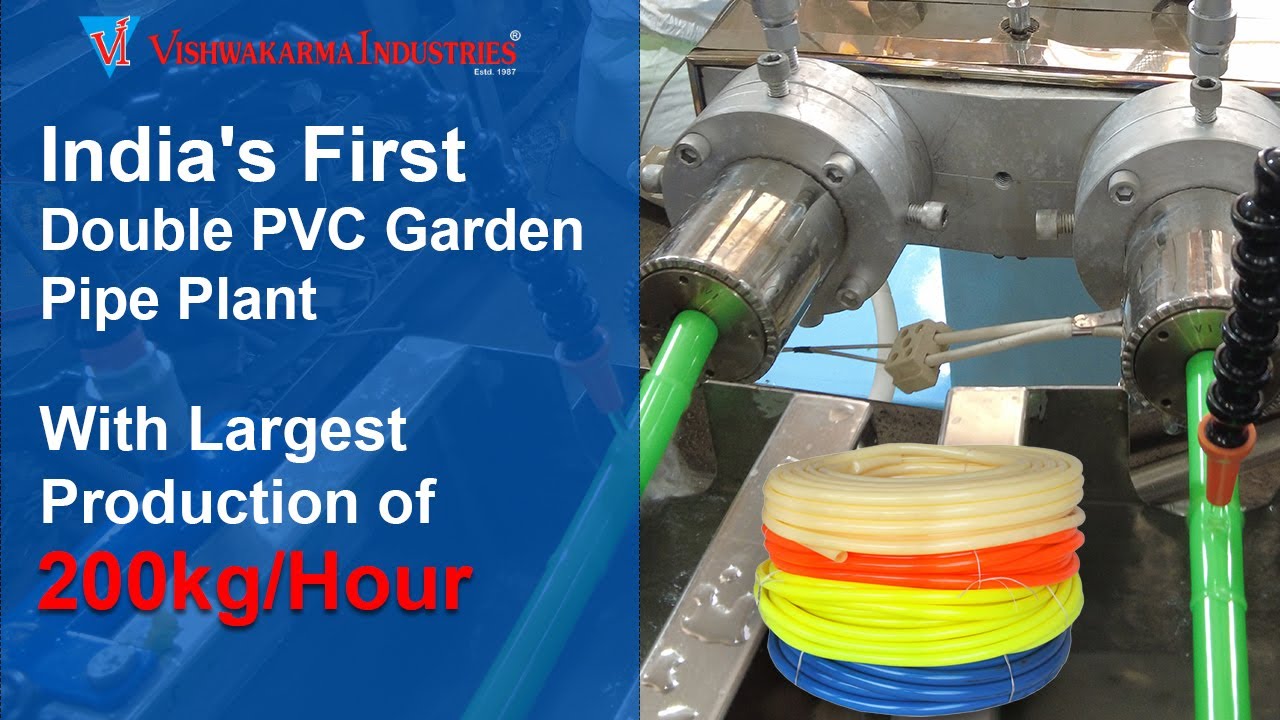

Introducing the Soft PVC Foam Pipe Plant from Vishwakarma Industries, a trusted name in PVC pipe manufacturing machinery in India. Designed with advanced extrusion technology, our PVC foam pipe plant offers high-speed production of lightweight, flexible, and durable foam pipes for garden, agricultural, and industrial applications.

Founded in 1987, Vishwakarma Industries is a leading PVC pipe machine manufacturer in Delhi, known for delivering reliable machinery with excellent after-sales service across India and to export markets.

Technical Specifications

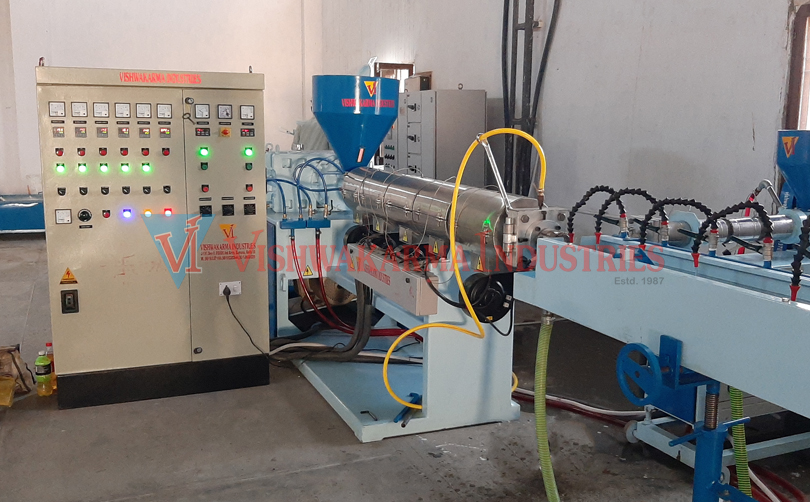

Our Soft PVC Foam Pipe Extrusion Line is engineered for consistent, high-quality foam pipe production:

- Pipe Diameter Range: 12mm to 50mm

- Output Capacity: 80–120 kg/hour (model-dependent)

- Extruder Type: Single screw extruder with high-speed and high-torque design

- Heating Zones: Multi-zone PID digital temperature controlled system

- Cooling System: Stainless steel water cooling tank with recirculating water sprayers

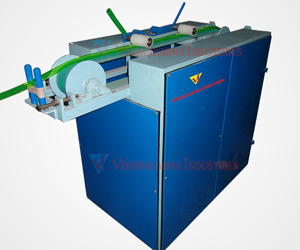

- Haul-off: Precision rubber belt haul-off unit for smooth pulling

- Cutting/Winding: Automatic cutter or coil winder as per requirement

- Power Consumption: Low power design for energy efficiency

- Automation: Available in semi-automatic and fully automatic versions

👉 Optional Add-ons: Color stripe unit, dual-layer jockey extruder for outer coating, and auto pipe winder.

Models

VI 90

Extruder Screw

90 mm

Main Motor

20 HP

Heating Load

20 HP

Berrel Blower Load

1.25 HP

Take-up

1 HP

High Speed Mixture

30 HP

Water Tank

10" x 10" x 195"

LD Ratio

25.:1

Installation Area

40' x 20'

Pipe Range

10mm to 40mm

Production Approx

125 Kg

Advance Features

Our Soft PVC Foam Pipe Manufacturing Machine incorporates the latest in plastic extrusion technology to ensure reliable performance, easy maintenance, and high output. It is built for manufacturers who want a cost-effective, energy-efficient solution for producing flexible PVC pipes.

The machine features a high-speed single screw extruder that ensures uniform melting and flow of the soft PVC material. The PID digital temperature control system allows precise heat management across multiple zones, ensuring consistent pipe quality. The stainless steel cooling tank not only enhances pipe strength through uniform cooling but also ensures corrosion-free durability, a major advantage for long-term use.

Key Features Include:

- ✔️User-Friendly: Easy-to-operate control panel with temperature display

- ✔️Durable: Heavy-duty structure for 24×7 industrial operations

- ✔️PID Digital Temperature Controller for stable extrusion performance

- ✔️High Performance for consistent and efficient pipe production

- ✔️Eco-Friendly: Designed to reduce environmental impact with sustainable materials.

- ✔️Low Power Consumption, helping reduce your operational costs

- ✔️Noise- and Vibration-Free Operation, ideal for indoor factory setup

- ✔️Automation Options: From semi-auto to fully automatic line

Conclusion

The Soft PVC Foam Pipe Plant from Vishwakarma Industries combines advanced extrusion technology with reliable performance to deliver lightweight, flexible, and durable PVC foam pipes. Whether you’re looking to start a PVC foam pipe manufacturing unit in India or expand your production capacity, our plant offers the perfect solution for profitable and sustainable business growth.

PVC Foam Garden Manufacturing Process

The PVC foam pipe plant follows a streamlined production process to ensure top-quality foam pipes:

Raw Material Mixing :-

Soft PVC granules, foaming agents, plasticizers, stabilizers, and color masterbatches are accurately mixed in high-speed mixers.

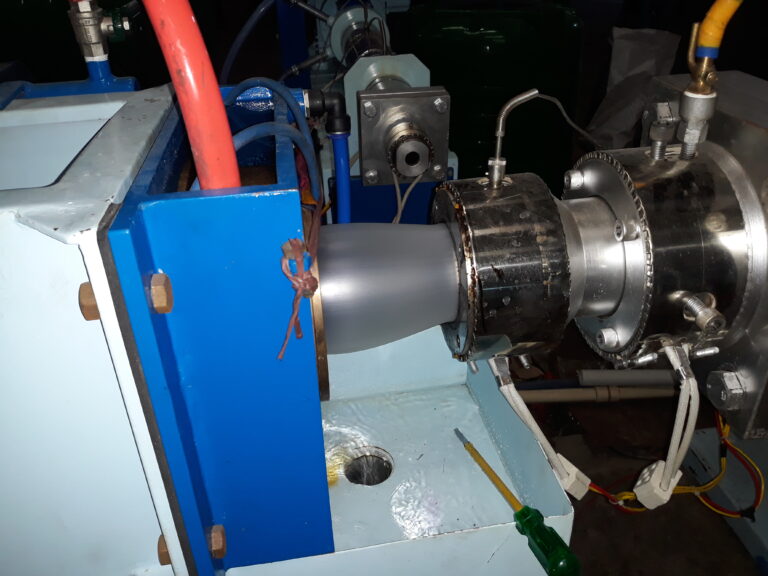

Melting Extrusion :-

The mixture is fed into the extruder, where it is uniformly melted. The foaming agent expands under controlled heat and pressure to form the foam core of the pipe.

Sizing & Shaping :-

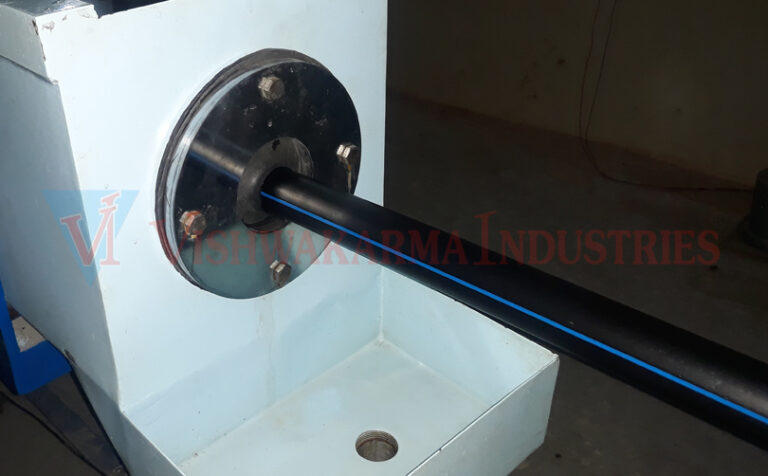

Molten material passes through a specialized die and vacuum calibration unit, forming precise dimensions and a smooth outer surface.

Pipe Cooling System :

The hot foam pipes pass through a stainless-steel cooling tank with water sprayers, stabilizing their shape and enhancing flexibility.

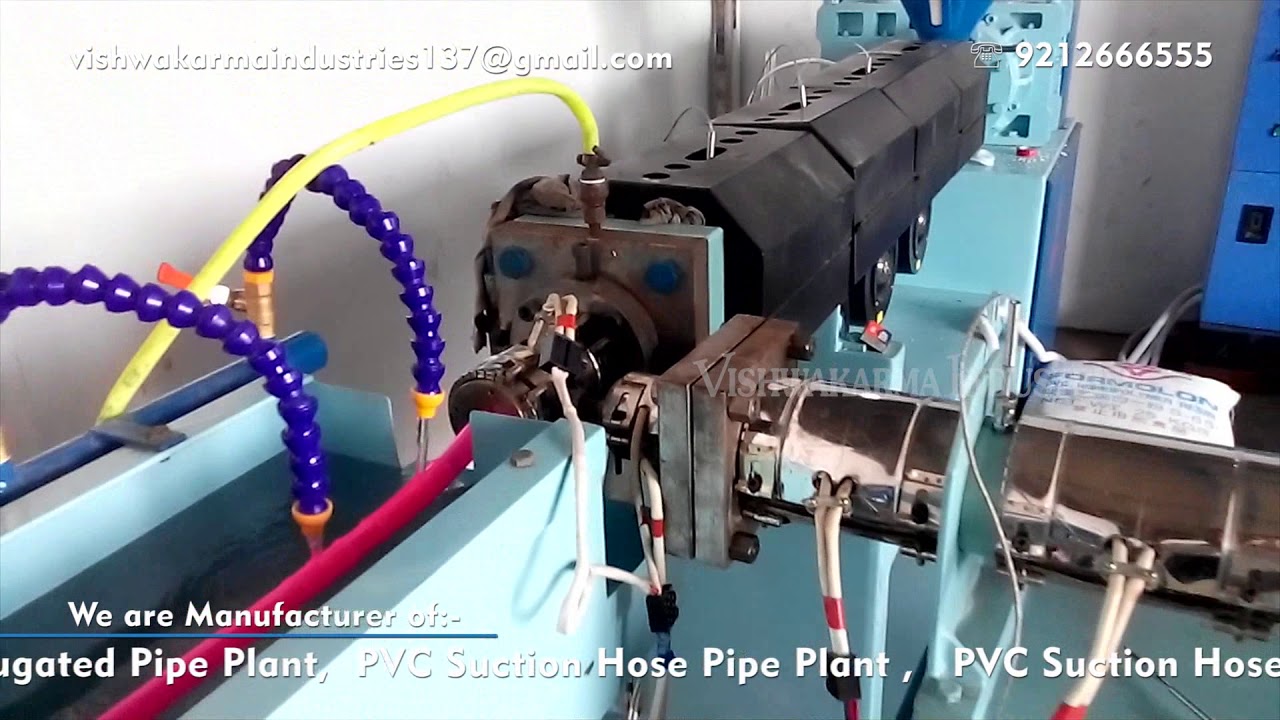

Patta Take-Up:

The cooled and calibrated pipe is pulled through the extrusion line using a haul-off unit. This unit maintains a consistent tension and speed to avoid any stretching or compression of the pipe. Finally, the pipe is cut to the desired length using an automated cutter. The cut pipes are then collected and inspected for quality before being packaged for distribution.

Control Panel:

The cooled and calibrated pipe is pulled through the extrusion line using a haul-off unit. This unit maintains a consistent tension and speed to avoid any stretching or compression of the pipe. Finally, the pipe is cut to the desired length using an automated cutter. The cut pipes are then collected and inspected for quality before being packaged for distribution.

PVC Soft Pipe Utilization

PVC Transparent Garden Pipes have a wide range of applications due to their versatility and durability. Here are some key sectors where these pipes are extensively used:

Water Supply:

PVC garden pipes are commonly used for watering gardens, lawns, and agricultural fields. Their flexibility and transparency make them easy to handle and monitor. These pipes are also used in irrigation systems for efficient water distribution.

Automobiles:

In the automotive industry, PVC pipes are used for various fluid transfer applications, including coolant lines, air conditioning systems, and windshield washer tubes. Their resistance to chemicals and high temperatures makes them ideal for under-the-hood applications.

Agriculture:

In addition to irrigation, PVC pipes are used in hydroponic systems for nutrient delivery and water circulation. Their resistance to UV radiation and chemicals makes them suitable for outdoor agricultural applications.

Food & Syrup Handling and Fluid & Chemical Transfer:

In the food and beverage industry, PVC pipes are used for handling and transferring liquids, syrups, and chemicals. Their non-toxic nature and ease of cleaning ensure that they meet the stringent hygiene standards required in this industry.

General Water Suction & Discharge:

PVC garden pipes are used for general water suction and discharge applications, such as draining pools, ponds, and water tanks. Their durability and resistance to abrasion make them suitable for these demanding applications.

Pharmaceutical Manufacture:

In the pharmaceutical industry, PVC pipes are used for transferring chemicals and fluids during the manufacturing process. Their transparency allows for easy monitoring of the flow and ensures compliance with quality standards.

EXPLORE OUR MACHINERY PRODUCTS

At Vishwakarma Industries, we manufacture and export top-grade machinery used in the plastic pipe industry, such as

Each of our machines is designed for durability, high output, low energy consumption, and minimal maintenance. Whether you’re starting a new unit or expanding capacity, we have a solution that fits your budget and technical needs.