PVC Rigid Pipe, UPVC Pipe, Casing Capping & Plumbing Pipe Extrusion Line

Playlist

6:47

6:13

6:12

3:51

5:14

6:46

5:21

PVC Rigid Pipe, UPVC Pipe, Casing Pipe & Plumbing Pipe Making Machine

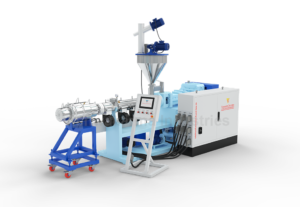

High-Speed PVC Pipe Extrusion Line Model VI-65x18

Looking for a reliable and efficient PVC Pipe Making Machine? Vishwakarma Industries presents the advanced PVC Twin Screw Extrusion Line – Model 65×18, designed for high output, low power consumption, and precision manufacturing. This machine is ideal for producing 20mm to 200mm PVC rigid pipes, plumbing pipes, UPVC pipes and casing pipes for domestic, commercial, and industrial applications.

Founded in 1987 by Mr. Kailash Chand, Vishwakarma Industries is known for delivering high-performance machines with excellent after-sales support, trusted across India and internationally.

Technical Specifications :-

The PVC Pipe Making Machine (Model 65x18) is designed to manufacture a wide range of high-quality pipes including PVC Rigid Pipes, UPVC Pipes, Casing Pipes, and Plumbing Pipes. Engineered for precision and durability, it’s ideal for manufacturers seeking consistent output, smooth finishes, and energy-efficient performance.

- Pipe Types: Supports production of rigid PVC, UPVC, casing, and plumbing pipes.

- Surface Finish: Delivers smooth internal and external surfaces with uniform wall thickness.

- Build Quality: Heavy-duty frame and components ensure long-term reliability and minimal maintenance.

- Extrusion Performance: Optimized screw-barrel design for consistent melting and material flow.

- Energy Efficiency: Low power consumption with high output, reducing operational costs.

- Scalability: Suitable for both small and large-scale manufacturing units.

📈 Ideal For:

- Manufacturers serving residential plumbing, building infrastructure, electrical conduit, and industrial casing applications.

- Units focused on cost-effective, high-volume, and quality-driven production.

Models

VI 65x18

Extruder Screw

65mm

Main Motor

30 HP

Heating Load

20 HP

Berrel Blower Load

1.25 HP

Extruder Vacuum

1 HP

Loader Motor

2 HP

Feeder Motor

3 HP

Screw Speed (RPM)

50

Vacuum Pump

3 HP

Take-up

5 HP

Pipe Cutter

3 HP

Air Compressor

5 HP

Vibrator Motor

0.5 HP

Hot & Cool Mixture

30 HP+7.5 HP

Water Tank

18"x18"x240"

LD Ratio

18:1

Installation Area

80'x50'

Pipe Range

20mm to 200mm

Production Approx

110 to 200 Kg.

Advance Features :-

The PVC Twin Screw 65×18 Pipe Making Machine from Vishwakarma Industries blends cutting-edge extrusion technology with industrial-grade durability. Engineered for high-volume, precision manufacturing, it’s the ideal solution for producing rigid PVC, UPVC, plumbing, and casing pipes with consistent quality and profitability.

🔧 Technology & Performance:

- ✅ Twin Screw Extruder (65×18) – Ensures uniform melting and smooth flow of rigid PVC material.

- ✅ PID Digital Temperature Control – Multi-zone precision heating for stable extrusion and consistent pipe quality.

- ✅ Stainless-Steel Cooling Tank – Enhances pipe strength through uniform cooling and offers corrosion-free durability.

- ✅ User-Friendly Control Panel – Digital temperature display for intuitive operation and quick adjustments.

- ✅ Heavy-Duty Frame – Built for continuous industrial use with minimal maintenance.

- ✅ Eco-Friendly Design – Reduces environmental impact through optimized energy use.

- ✅ Low Power Consumption – Delivers high output while keeping operational costs low.

- ✅ Low Noise & Vibration-Free Operation – Suitable for indoor factory environments.

- ✅ Automation Options – Available in both semi-automatic and fully automatic configurations.

📏 Pipe Range:

- Designed to produce pipes from 20mm to 200mm, including:

- PVC Rigid Pipes

- UPVC Pipes

- Plumbing Pipes

- Electrical Conduit & Casing Pipes

🏆 Why It Stands Out:

This model is a top choice for manufacturers across India, offering a powerful combination of performance, durability, and affordability. It’s built to support long-term growth with consistent output and minimal downtime.

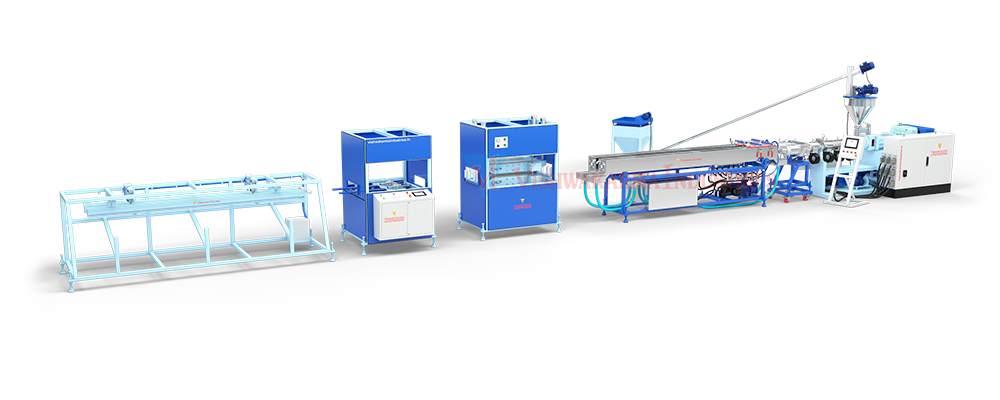

Manufacturing Process of PVC Rigid Pipe, UPVC Pipe, Casing Pipe & Plumbing Pipe Making Machine

The PVC Rigid Pipe Making Machine Model 65×18 from Vishwakarma Industries, Delhi follows a highly efficient and streamlined manufacturing process designed to produce strong, durable, and high-quality Rigid pipes. The process ensures minimal material wastage, uniform wall thickness, and maximum production speed, making it ideal for PVC Rigid pipe manufacturing units in India and export markets.

Our machine enables consistent production of Rigid pipes that meet national and international standards for Casing protection, ensuring safety and reliability in every batch.

Here’s how the process works, step-by-step:

Raw Material Mixing in Hot and Cool Mixture :-

The process begins with the precise mixing of rigid PVC resin, stabilizers, lubricants, fillers (like calcium carbonate if required), and color masterbatches. This mixture is thoroughly blended using high-speed hot and cool mixers to ensure uniform dispersion of all additives. Proper raw material preparation is critical for smooth extrusion, dimensional accuracy, and long-lasting durability of the pipes.

Melting and Extruding :-

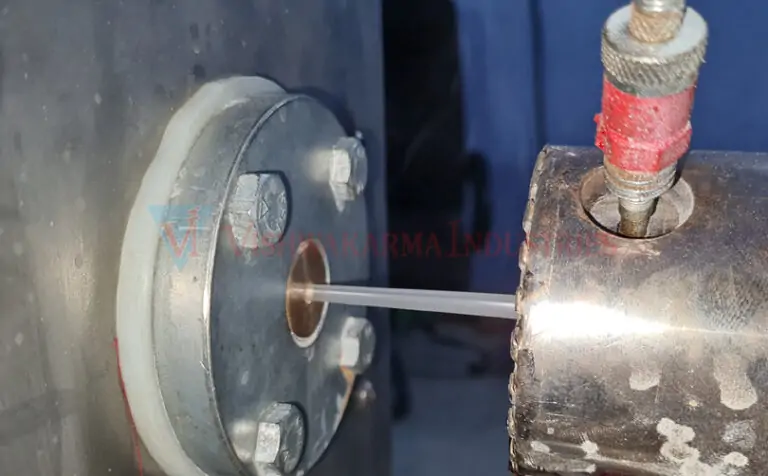

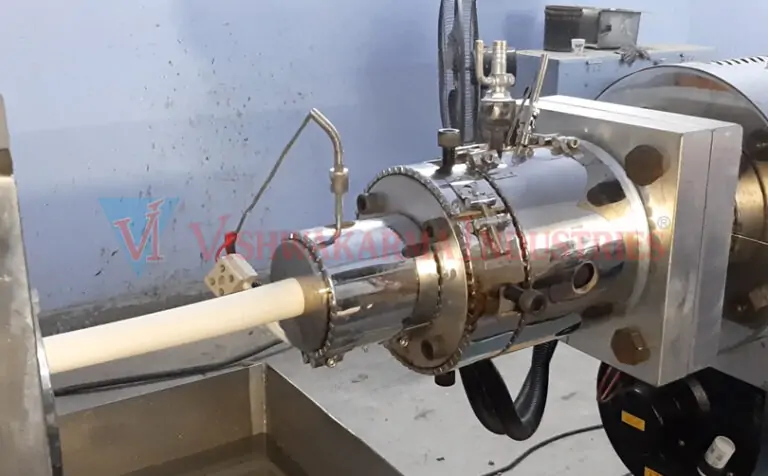

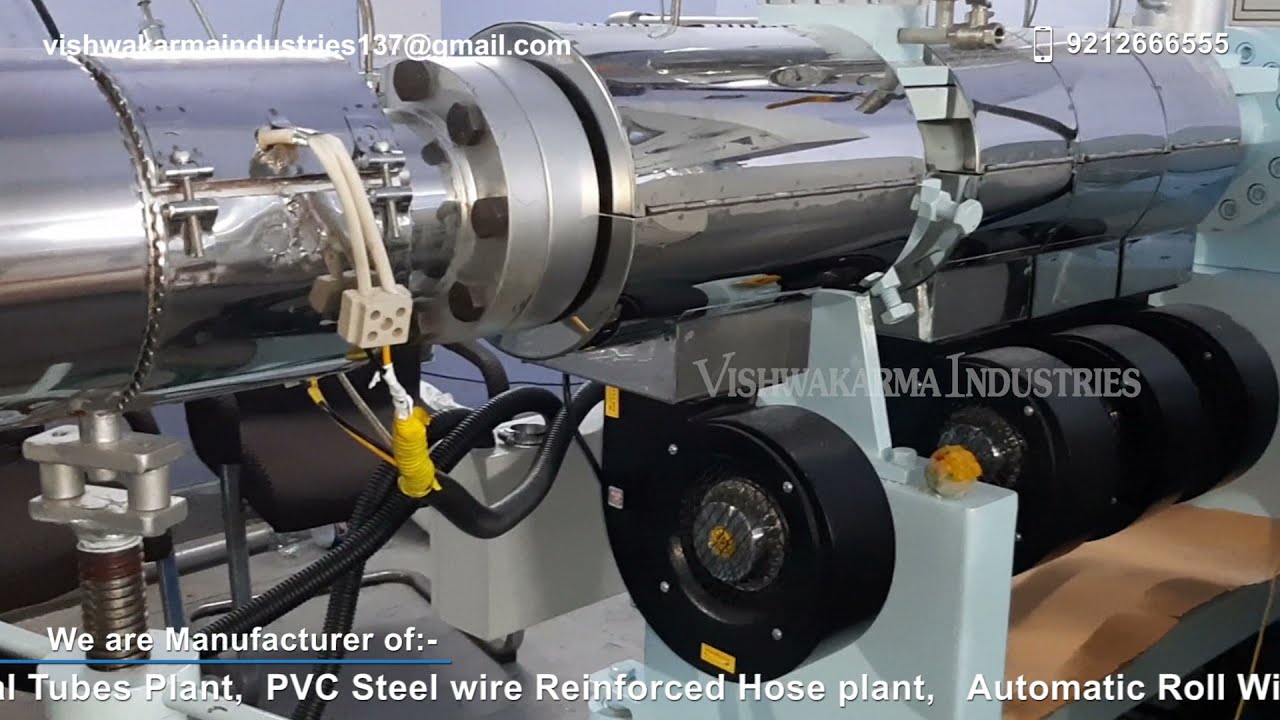

The blended rigid PVC material is fed into the Twin screw extruder, where it is melted uniformly. With PID-controlled heating zones, the rigid PVC compound is gradually heated and pushed through the screw and barrel, maintaining flow consistency. This step is crucial for achieving uniform wall thickness and a smooth inner surface of the pipe.

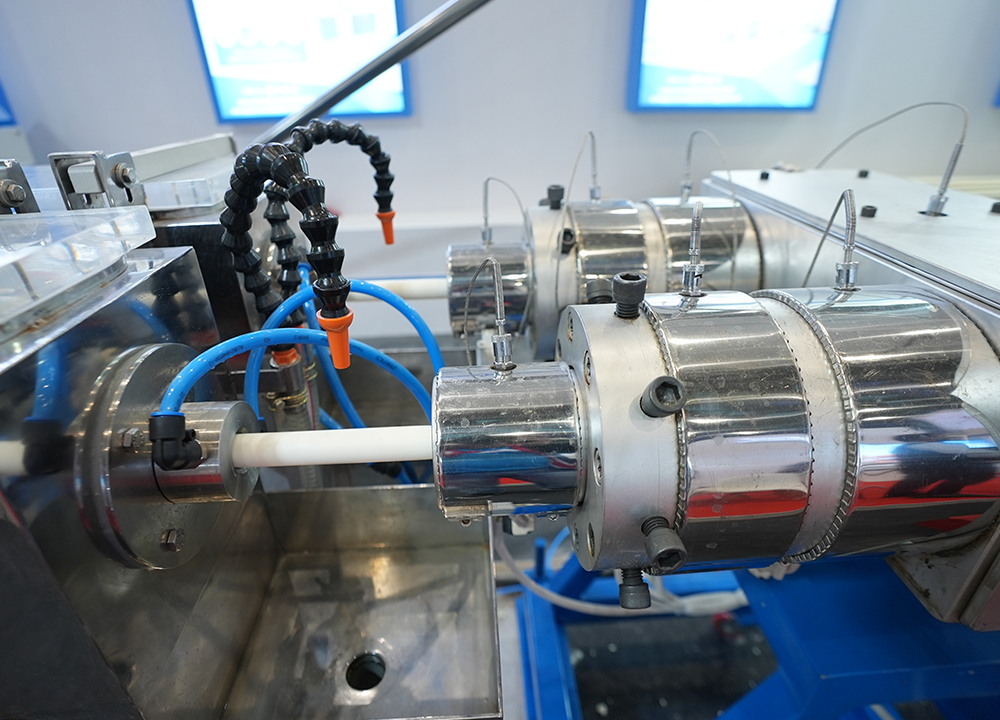

Sizing and Shaping :-

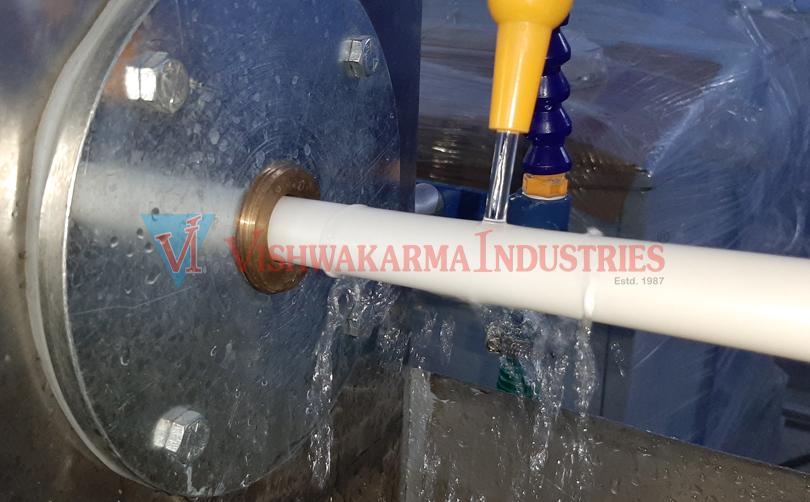

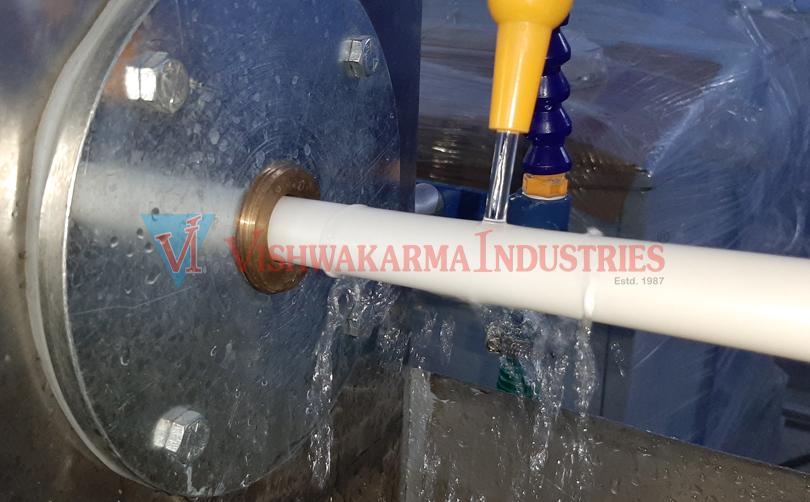

The molten PVC is passed through a specially designed Rigid pipe die head, which shapes the pipe into the required diameter and wall thickness. The pipe then enters the vacuum calibration unit and sizing sleeve, ensuring accurate dimensions and a smooth surface finish, as per ISI or international standards.

Pipe Cooling System :-

The hot, shaped conduit pipe is passed through a stainless-steel water-cooling tank to solidify and retain its precise shape. Efficient cooling prevents deformation and ensures the pipe meets strict dimensional tolerances. The cooling tank is equipped with water sprayers and a recirculating pump for optimal cooling efficiency.

Haul-Off Unit :-

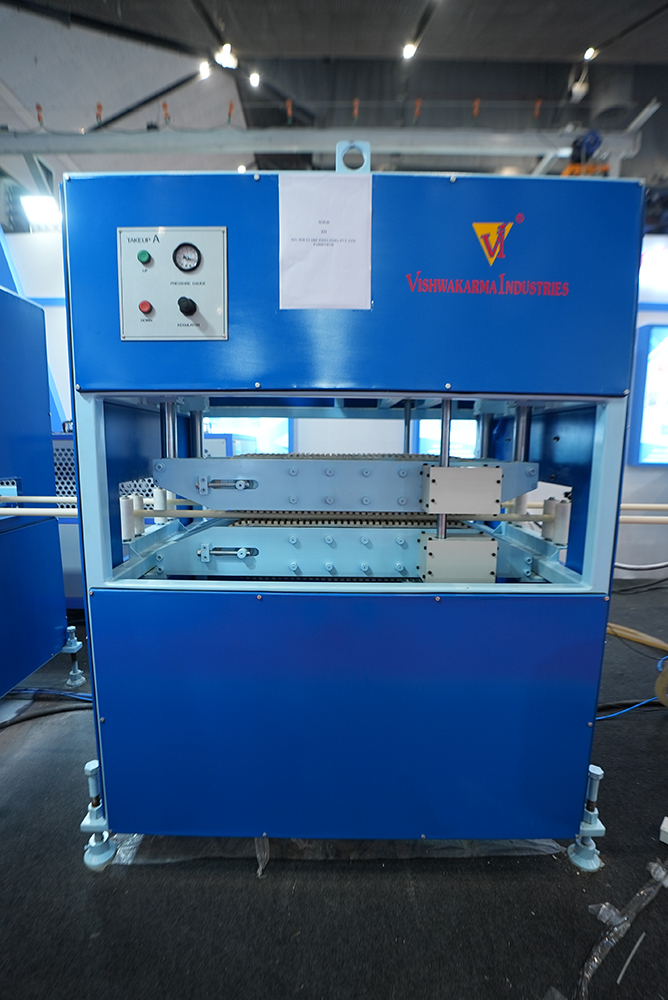

The haul-off or traction unit pulls the pipe uniformly from the extruder. Adjustable speed controls ensure constant pulling tension, preventing pipe stretching or deformation. This unit works in perfect sync with the cutting unit, delivering pipes of precise length.

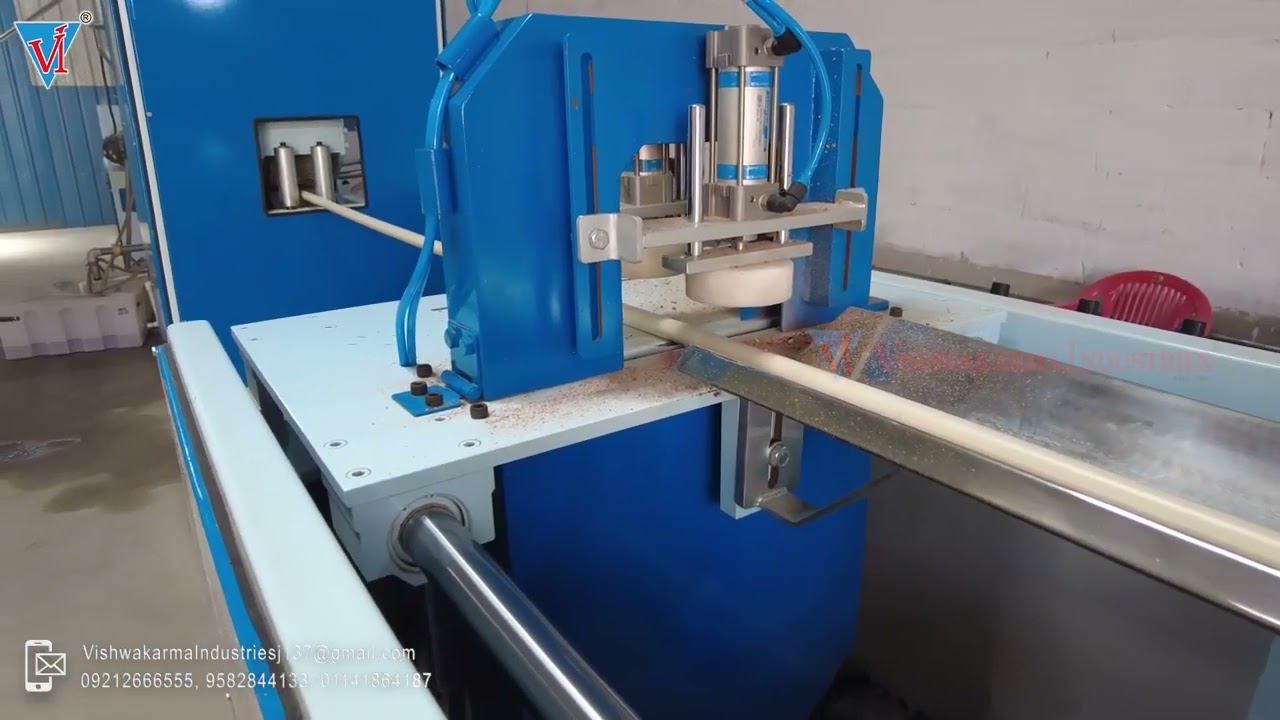

Automatic Cutting Unit :-

An automatic cutting unit cuts the pipe into standard lengths as per customer specifications, ensuring smooth, burr-free edges ready for bundling and dispatch.

PLC Control Panel Control Panel :-

The entire PVC Rigid Pipe Making Machine is operated through a user-friendly PLC control panel. This panel integrates key functions such as:

- Speed settings for extruder, haul-off, and cutter

- PID temperature controls for precise heating zone management

- Safety alarms for over-temperature, overload, or system faults

The PLC system allows operators to monitor, adjust, and synchronize all processes in real-time, ensuring consistent quality and high production efficiency. The intuitive interface reduces operator error and improves overall plant productivity.

PVC Rigid Pipe, UPVC Pipe, Casing Pipe & Plumbing Pipe Utilization & Applications

Designed to produce PVC Rigid, UPVC, Casing, and Plumbing Pipes, this machine supports a wide range of infrastructure and utility applications.

⚡ Residential & Commercial Plumbing – Leak-proof, durable piping for water supply and drainage systems.

- 🏢 UPVC Pipe Systems for Buildings – Ideal for structural piping in high-rise and commercial complexes.

- 🏭 Industrial Cable & Fluid Management – Ensures safe routing and containment in demanding industrial environments.

- 🛠 Electrical Wiring Protection (Conduit Pipes) – Flame-retardant and insulating pipes for secure electrical installations.

- 🚧 Casing & Underground Cable Protection – Robust shielding for buried utilities and telecom infrastructure.

🌍 Performance Benefits:

Pipes produced on this line are:

- High-strength, flame-retardant, and corrosion-resistant

- Lightweight, easy to install, and cost-effective

- Provide excellent insulation and long-term reliability

These qualities make them ideal for residential, commercial, and industrial projects across India and international markets, supporting modern infrastructure with safety and efficiency.

EXPLORE OUR MACHINERY PRODUCTS

At Vishwakarma Industries, we manufacture and export top-grade machinery used in the plastic pipe industry, such as

Each of our machines is designed for durability, high output, low energy consumption, and minimal maintenance. Whether you’re starting a new unit or expanding capacity, we have a solution that fits your budget and technical needs.