PVC Rigid, UPVC & Plumbing Pipe Making Machine

Model 52x22 and 52x25

Playlist

6:47

6:13

6:12

3:51

5:14

6:46

5:21

PVC Rigid, UPVC & Plumbing Pipe Making Machine

Model 52x22 and 52x25

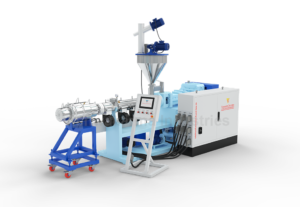

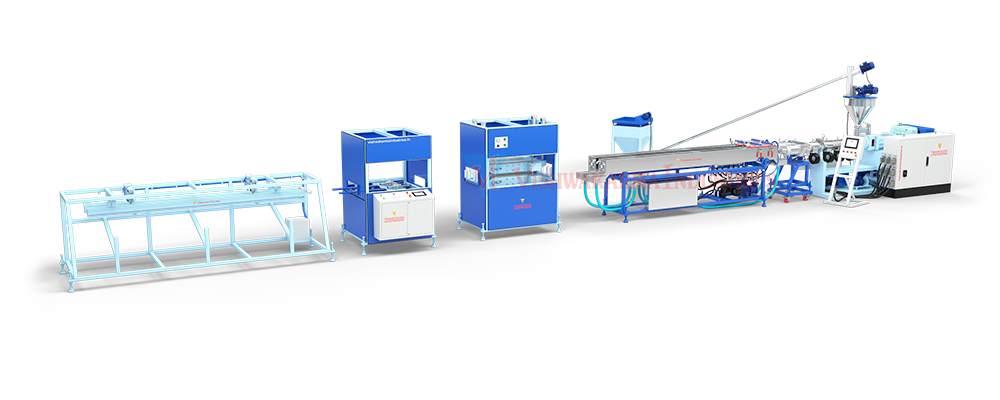

Looking for a reliable PVC Rigid and Plumbing Pipe Making Machine? Vishwakarma Industries offers the advanced PVC Pipe Extrusion Line – Models 52×22 and 52×25. These machines deliver high output, low energy use, and precise manufacturing. They are ideal for producing PVC rigid pipes, plumbing pipes, UPVC pipes, electrical conduit pipes, and casing pipes from 20mm to 160mm diameter. The pipes are widely used in domestic, commercial, and industrial projects. Vishwakarma Industries was founded in 1987 by Mr. Kailash Chand. The company is known for reliable, high-performance machines and excellent after-sales service across India and abroad.

Technical Specifications :-

The PVC Pipe Making Machine (Models 52x22 and 52x25) is made by Vishwakarma Industries, Delhi. It produces high-quality pipes from rigid PVC and UPVC material. The pipes have excellent strength, durability, and a smooth finish. This machine is suitable for both small and large manufacturing plants. It offers consistent output, saves energy, and is easy to operate.

✅ Models: 52x22 and 52x25 PVC Twin Screw Extrusion Line

✅ Pipe Range: 20mm – 160mm (Rigid PVC, UPVC, Plumbing, Electrical Conduit, and Casing Pipes)

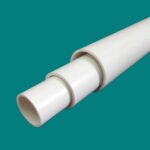

✅ Material: Rigid PVC/UPVC with high strength and smooth surface finish

✅ Performance: Consistent output with energy-efficient operation

✅ Design: Easy to operate, durable, and suitable for continuous production

✅ Applications: Domestic, commercial, and industrial pipe manufacturing units

Models

VI 52x22

VI 52x25

Extruder Screw

52 mm

52 mm

Main Motor

20 HP

25 HP

Heating Load

15 HP

15 HP

Berrel Blower Load

1 HP

1 HP

Extruder Vacuum

1 HP

1 HP

Loader Motor

2 HP

2 HP

Feeder Motor

3 HP

3 HP

Screw Speed (RPM)

50

50

Vacuum Pump

3 HP

3 HP

Take-up

2 HP

2 HP

Pipe Cutter

2 HP

3 HP

Air Compressor

5 HP

5 HP

Vibrator Motor

0.5 HP

0.5 HP

Hot & Cool Mixture

30 HP+7.5 HP

30 HP+7.5 HP

Water Tank

12"x12"x145"

12"x12"x145"

LD Ratio

22:1

25:1

Installation Area

100'x50'

100'x50'

Pipe Range

20mm to 100mm

20mm to 125mm

Production Approx

110 to 170 kg

110 to 170 kg

Advance Features :-

Our PVC Pipe Making Machine uses the latest plastic extrusion technology. It delivers reliable performance, easy maintenance, and high output. This machine is designed for manufacturers who need a cost-effective and energy-efficient solution for producing different types of PVC pipes. Twin Screw Extruder: High-speed design ensures uniform melting and smooth flow of rigid PVC material. PID Temperature Control: Digital system manages heat precisely across multiple zones for consistent pipe quality. Stainless Steel Cooling Tank: Provides uniform cooling for stronger pipes and resists corrosion, ensuring long-term durability.

Key Features Include:

✅ Twin Screw Extruder 52x22 & 52x25 for uniform material melting & smooth flow

✅ Pipe size support from 20mm to 160mm

✅ User-Friendly: Easy-to-operate control panel with temperature display

✅ Durable: Heavy-duty structure for 24x7 industrial operations

✅ PID Digital Temperature Controller for stable extrusion performance

✅ High Performance for consistent and efficient pipe production

✅ Eco-Friendly Design to reduce environmental impact

✅ Low Power Consumption, helping reduce operational costs

✅ Noise- and Vibration-Free Operation

✅ Automation Options: Semi-auto and fully automatic lines available

These features make it the best machine for PVC rigid pipe manufacturing in India. It offers strong performance, long-lasting durability, and affordable operation.

Conclusion

The PVC Pipe Making Machine (Models 52x22 & 52x25) from Vishwakarma Industries is the best choice for manufacturing high-quality pipes. It can produce PVC rigid pipes, plumbing pipes, UPVC pipes, electrical pipes, and casing pipes from 20mm to 160mm. The machine combines advanced technology with a strong design and reliable support. It ensures efficient, precise, and profitable production for any PVC pipe plant.

👉 Choose Vishwakarma Industries for superior technology, consistent quality, and long-term value.

Manufacturing Process of PVC Rigid & Plumbing Pipe

The PVC Plumbing Pipe Making Machine (Models 52×22 & 52×25) from Vishwakarma Industries, Delhi uses an efficient manufacturing process. It produces strong, durable, and high-quality PVC rigid pipes. The process reduces material waste, keeps wall thickness uniform, and delivers maximum production speed. This makes it ideal for PVC plumbing pipe manufacturing units in India and export markets. Our machine also produces conduit pipes that meet both national and international standards. They provide safe and reliable protection for electrical wiring and plumbing in every batch.

Here’s how the process works, step-by-step

Raw Material Mixing in Hot and Cool Mixture :-

The process starts with mixing rigid PVC resin, stabilizers, lubricants, fillers, and color masterbatches. The blend is prepared in high-speed hot and cool mixers to spread additives evenly. Proper raw material preparation ensures smooth extrusion, accurate dimensions, and durable PVC pipes.

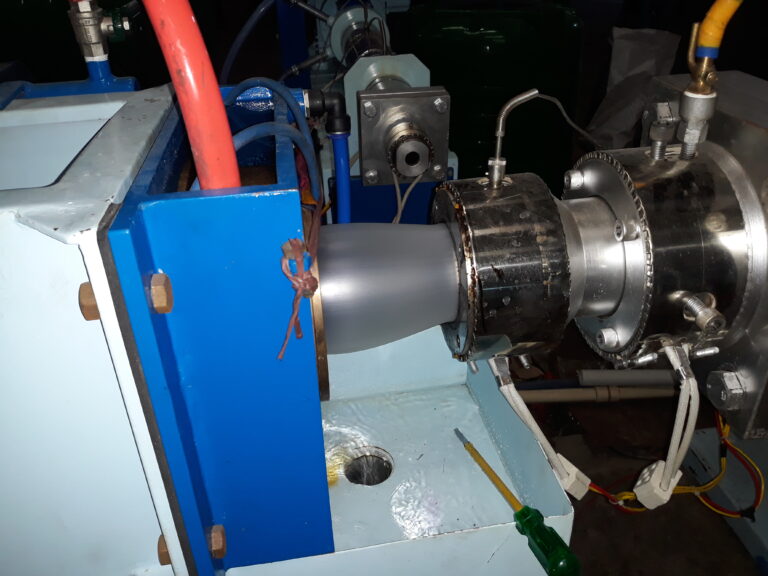

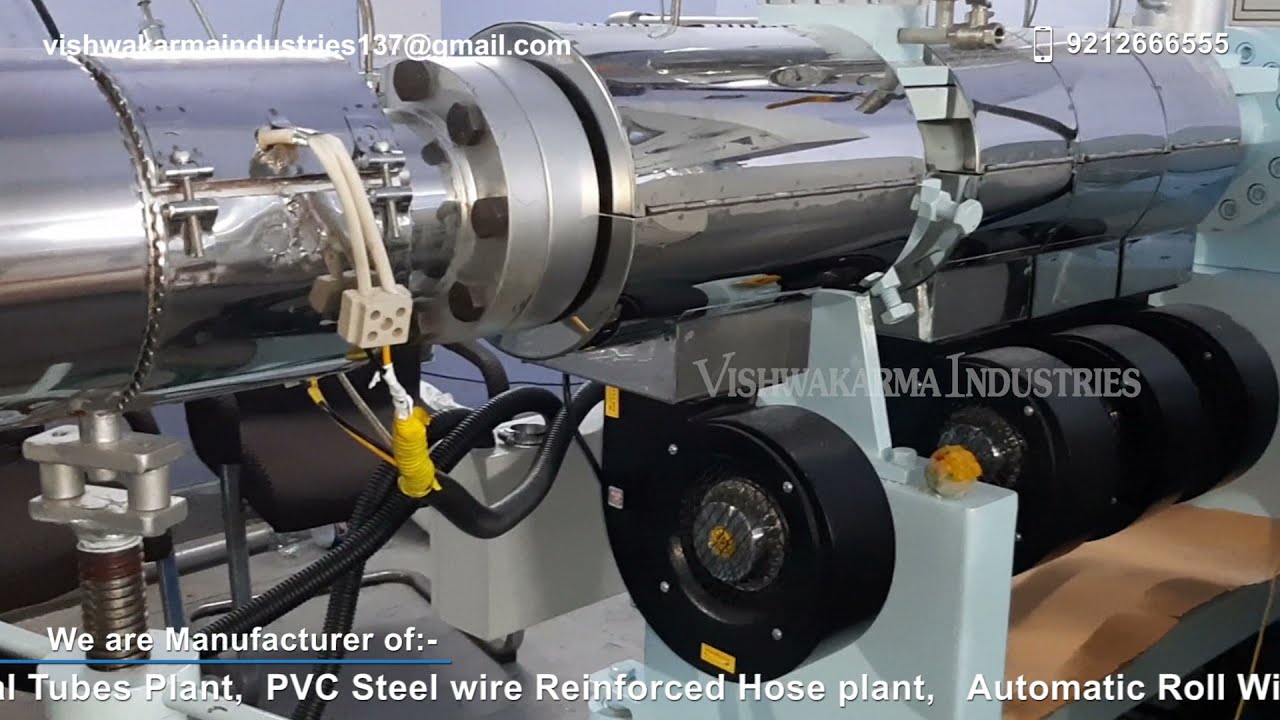

Melting and Extruding :-

The blended rigid PVC material is fed into the Twin screw extruder, where it is melted uniformly. With PID-controlled heating zones, the rigid PVC compound is gradually heated and pushed through the screw and barrel, maintaining flow consistency. This step is crucial for achieving uniform wall thickness and a smooth inner surface of the Pvc pipeThe blended rigid PVC material is fed into the Twin screw extruder, where it is melted uniformly. With PID-controlled heating zones, the rigid PVC compound is gradually heated and pushed through the screw and barrel, maintaining flow consistency. This step is crucial for achieving uniform wall thickness and a smooth inner surface of the Pvc pipe

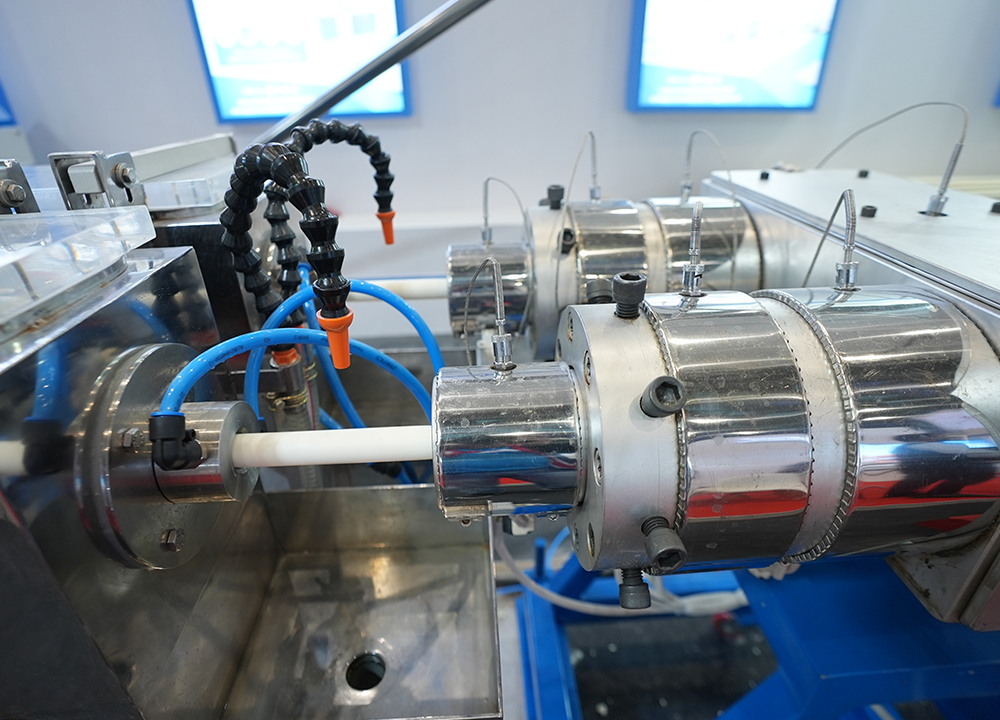

Sizing and Shaping :-

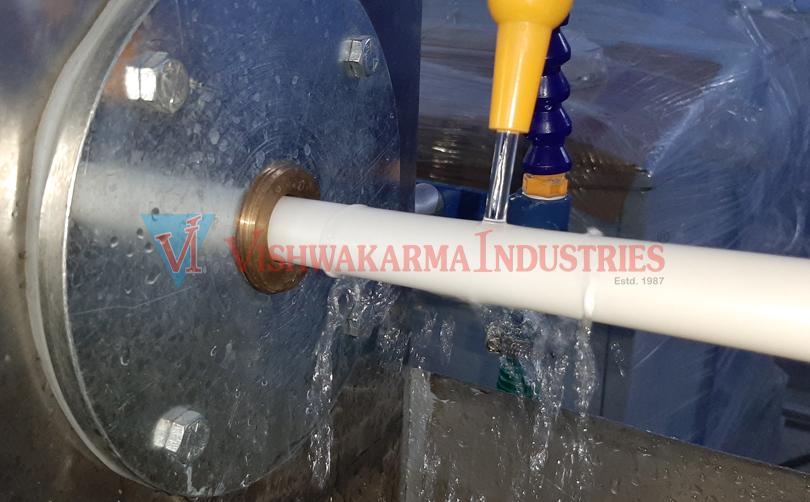

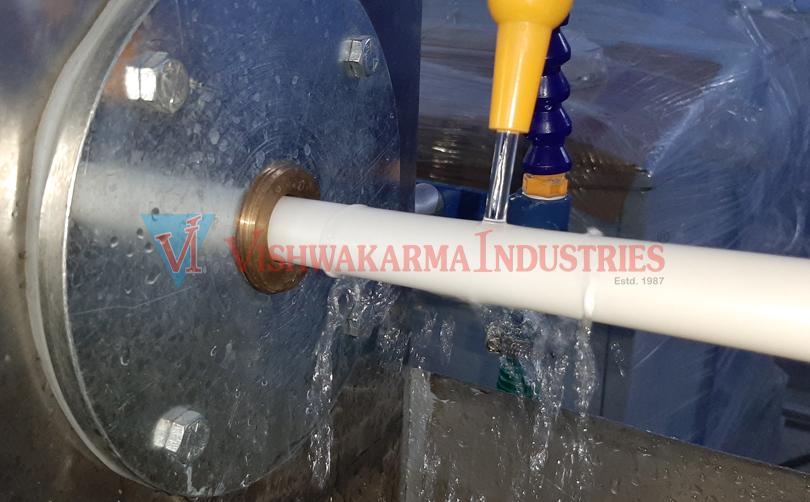

The molten PVC passes through a specially designed die head. This shapes the pipe to the required diameter and wall thickness. Next, the pipe enters the vacuum calibration unit and sizing sleeve. These ensure accurate dimensions and a smooth surface finish that meets ISI and international standards.

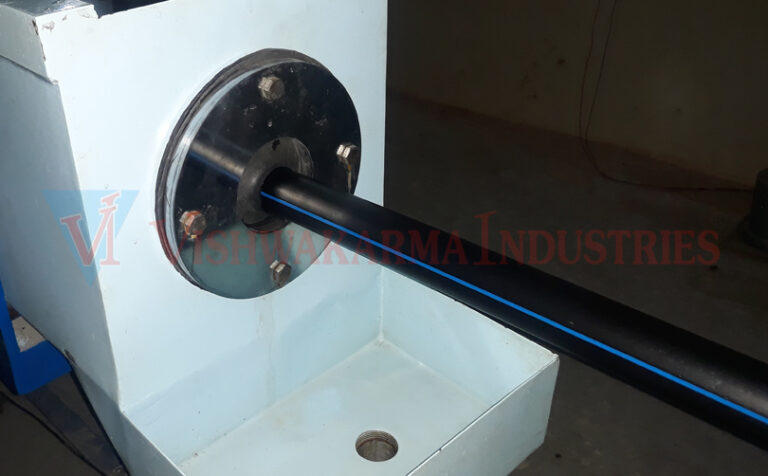

Pipe Cooling System :-

The hot, shaped PVC pipe is passed through a stainless-steel water-cooling tank to solidify and retain its precise shape. Efficient cooling prevents deformation and ensures the pipe meets strict dimensional tolerances. The cooling tank is equipped with water sprayers and a recirculating pump for optimal cooling efficiency.

Haul-Off Unit :-

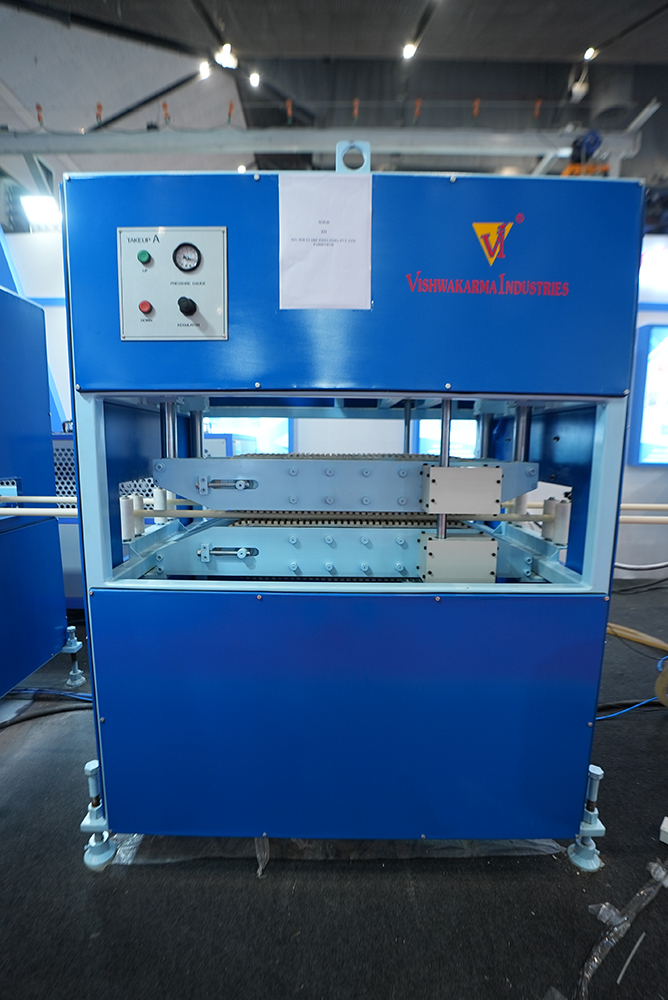

The haul-off or traction unit pulls the PVC pipe uniformly from the extruder. Adjustable speed controls ensure constant pulling tension, preventing pipe stretching or deformation. This unit works in perfect sync with the cutting unit, delivering pipes of precise length.

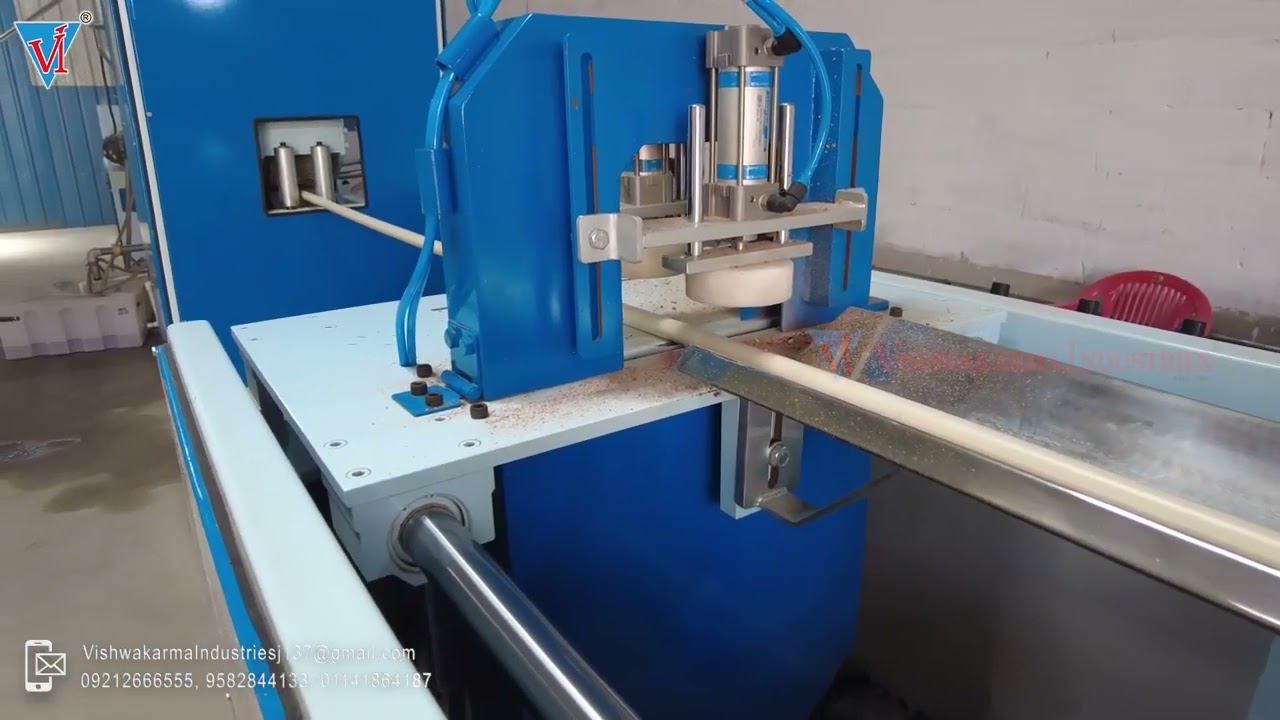

Automatic Cutting Unit :-

The automatic cutting unit cuts the pipe into standard lengths as per customer needs. It delivers smooth, burr-free edges. The pipes are then ready for bundling and dispatch.

PLC Control Panel Control Panel :-

The PVC Rigid Pipe Making Machine is controlled through a user-friendly PLC panel. This panel manages key functions such as:

- Speed settings for the extruder, haul-off, and cutter

- PID temperature controls for heating zones

- Safety alarms for over-temperature, overload, or system faults

The PLC system lets operators monitor, adjust, and synchronize all processes in real time. It ensures consistent quality and high production efficiency. The simple interface reduces operator errors and improves overall plant productivity.

PVC Rigid, UPVC & Plumbing Utilization & Applications

Our advanced extrusion machines empower manufacturers to produce high-performance rigid pipes tailored for diverse sectors, ensuring strength, safety, and reliability across every application.

🌍 Key Applications

- 🏠 Residential Plumbing – Leak-proof, durable pipes for safe water supply and drainage.

- 🏢 Commercial Infrastructure – UPVC systems for modern buildings, offering flame-retardant and corrosion-resistant performance.

- 🏭 Industrial Solutions – Heavy-duty cable and fluid management pipes built for demanding environments.

- ⚡ Electrical Wiring Protection – Conduit pipes with excellent insulation and mechanical strength.

- 🚧 Underground Cable Casing – Long-lasting protection against moisture, soil pressure, and external damage.

🔑 Machine Advantages

- Precision Engineering – Consistent pipe dimensions and smooth finishes.

- High Output Efficiency – Optimized for large-scale production with reduced energy consumption.

- Versatile Design – Supports PVC rigid, UPVC, and plumbing pipe variants.

- Global Standards – Built to meet both Indian and international quality benchmarks.

💡 Why Choose Vishwakarma Pipes

The PVC rigid pipes produced by our machines are:

- Strong & Durable – Built to withstand years of use.

- Flame-Retardant – Enhancing safety in residential and industrial projects.

- Corrosion-Resistant – Reliable even in humid or underground conditions.

- Easy to Install – Saving time and labor costs.

👉 These qualities make them ideal for residential, commercial, and industrial projects in India and across export markets, where trust, performance, and compliance are non-negotiable.

EXPLORE OUR MACHINERY PRODUCTS

At Vishwakarma Industries, we manufacture and export top-grade machinery used in the plastic pipe industry, such as

Each of our machines is designed for durability, high output, low energy consumption, and minimal maintenance. Whether you’re starting a new unit or expanding capacity, we have a solution that fits your budget and technical needs.