PVC Suction Hose Pipe Plant

Playlist

4:31

4:22

PVC Suction Hose Pipe Plant

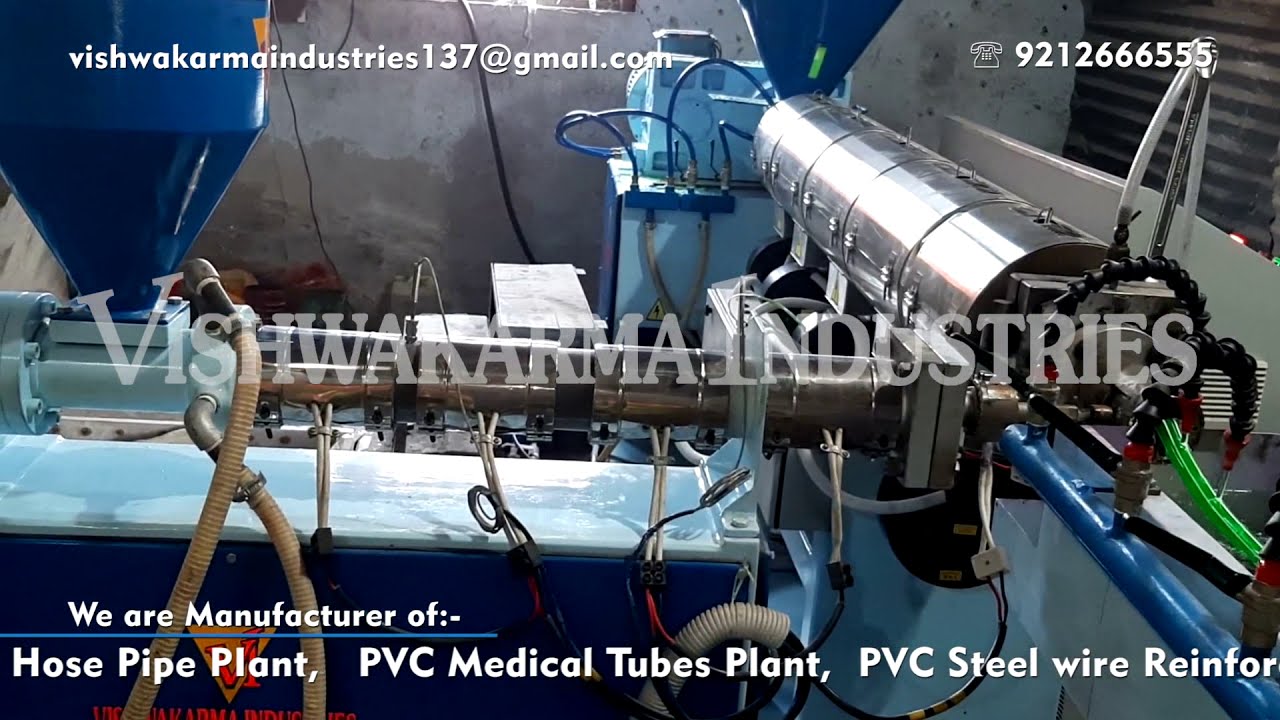

The PVC Suction Hose Pipe Plant from Vishwakarma Industries is a high-performance machine. It produces durable, flexible, and heavy-duty suction hose pipes. Our plant is built with precision. It is ideal for industries and entrepreneurs who want to start or expand PVC suction pipe manufacturing in India or abroad. Vishwakarma Industries has been a trusted name since 1987. We are a Delhi-based manufacturer of PVC pipe machines. Our machines are reliable, cost-effective, and easy to operate. We also provide strong after-sales support.

Technical Specifications

Our PVC suction hose pipe extrusion line delivers consistent, high-speed output with excellent quality.

Pipe Diameter Range: ¾” to 10” (custom options available)

Output Capacity: 50 kg/hour to 150 kg/hour (model dependent)

Extruder Type: Single screw extruder + high torque motor + optional co-extruder for color stripes

Reinforcement: Integrated rigid PVC spiral reinforcement for added strength

Heating Zones: PID-controlled multi-zone heating system

Cooling System: Water cooling trough with high-efficiency sprayers

Automation: Available in semi-automatic and fully automatic versions

Power Consumption: Designed for low power usage with high efficiency

Optional Add-ons: Color stripe unit, online marking/branding unit, automatic coil winder.

Models

VI 40x50

VI 50x65

VI 65x75

VI 75x90

Extruder Screw

40mm, 50mm

50mm, 65mm

65mm, 75mm

75mm, 90mm

Main Motor

5 HP. 7.5 HP

7.5 HP. 15 HP

15 HP, 20 HP

20 HP, 25 HP

Heating Load

7 HP. 10 HP

10 HP. 15 HP

15 HP, 17 HP

17 HP..20 HP

Berrel Blower Load

1.25 HP

1.5 HP

1.5 HP

2.25 HP

Take-up

2 HP

2 HP

2 HP

3 HP

Mixture For Rigid

20 HP

20 HP

20 HP

20 HP

Mixture For Rigid

25 HP

25 HP

25 HP

25 HP

Water Tank

8"x8"x105'

12"x12"x105'

14"x10"x 105'

18"x10"x 105'

LD Ratio

25:1.25:1

25:1.25:1

25:1.25:1

25:1.25:1

Installation Area

20' x 125'

20' x 125'

20' x 125'

20' x 125'

Pipe Range

34" x 1 1/½"

1" x 4"

1 1/2" x 8"

3" x 10"

Production Approx

20 Kg

80 Kg

100 Kg

150 Kg

Advance Features

Our PVC Suction Hose Pipe Plant uses modern extrusion technology. It delivers reliable performance, easy maintenance, and high output. The plant is cost-effective and energy-efficient. It is perfect for making spiral-reinforced PVC suction pipes for industrial, agricultural, and commercial use. The plant has a high-speed single screw extruder. This ensures uniform melting and smooth flow of the PVC compound. A spiral reinforcement applicator adds strength and flexibility to the pipes. The PID digital temperature control system manages heat across multiple zones. This guarantees consistent pipe quality with uniform wall thickness. The stainless-steel water-cooling tank provides uniform cooling. It improves pipe stability and prevents corrosion, making the plant durable for heavy-duty use.

Key Features-

✅ Heavy-duty pipe production: Built to manufacture pipes that can handle vacuum and pressure for industrial and agricultural use.

✅ High-speed, stable extrusion: Uniform material flow ensures superior pipe quality and wall thickness consistency.

✅ Energy efficient: Low power consumption design for cost savings.

✅ Strong spiral reinforcement: Integrated PVC rigid spiral provides flexibility with strength.

✅ User-friendly operation: Intuitive control panel with adjustable settings for speed, temperature, and tension.

✅ Low maintenance: Robust build ensures long-term operation with minimal downtime.

✅ Noise- and vibration-free operation: Ideal for modern PVC suction hose manufacturing plants.

✅ Eco-friendly: Minimal material wastage and optimized process for reduced environmental impact.

Conclusion

The PVC Suction Hose Pipe Plant from Vishwakarma Industries offers advanced technology, energy savings, and durability. It produces high-quality suction pipes for agriculture, industry, and commercial use. Whether you are starting a new plant or upgrading an existing one, this solution ensures high productivity and long-term success.

Manufacturing Process of PVC Suction Hose Pipe

The manufacturing process of PVC Transparent Garden Pipes involves several critical steps, each contributing to the final product’s quality. Here’s an overview of the process

Raw Material Preparation:

In making PVC suction hose pipes, Soft PVC and Rigid PVC are prepared separately. This ensures the pipe has the best quality and strength.

Soft PVC Mixing: – Soft PVC compounds are blended with plasticizers, stabilizers, lubricants, and color masterbatches in high-speed mixers. This mixture makes the flexible part of the hose. It gives the pipe elasticity and bendability.

Rigid PVC Mixing: – Rigid PVC is blended with stabilizers and lubricants in a separate mixer. This mixture forms the spiral reinforcement (helix). The helix gives the suction pipe strength. It helps the pipe withstand vacuum and pressure.

✅ Mixing soft and rigid PVC separately gives better results.

- It ensures uniform material consistency.

- It improves adhesion between flexible and rigid layers.

- It produces high-quality, durable, and reliable suction hose pipes.

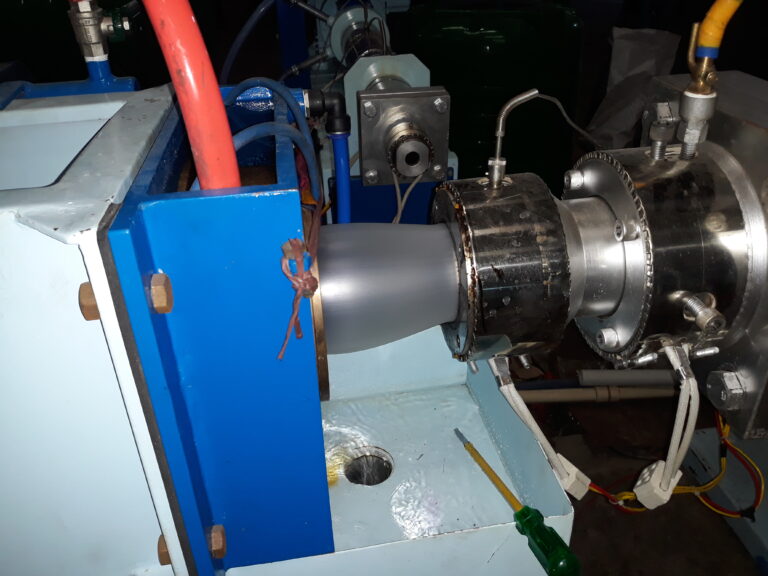

Melting & Extrusion :

The blended raw material is fed into a high-speed single screw extruder, where it is melted uniformly. Multi-zone PID-controlled heaters ensure the PVC compound flows smoothly and maintains consistent quality.

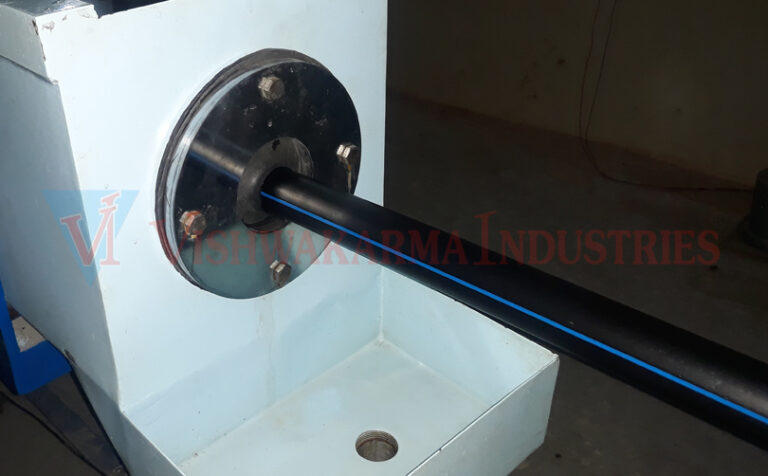

Shaping and Sizing:

The hot extruded and reinforced pipe passes through precision forming tools and sizing sleeves. This step ensures that the suction pipe achieves accurate outer diameter, wall thickness, and a smooth, even surface finish.

Pipe Cooling System :

After shaping, the pipe enters a stainless-steel water-cooling tank. The tank has high-pressured sprayers and recirculating pumps.

✅ Uniform cooling along the pipe’s entire length

✅ Dimensional stability without deformation

✅ Enhanced durability and flexibility of the suction pipe

Farmer Take-up:

In this stage, the pipe passes through a specially designed Farmer Take-up unit. The unit pulls the pipe smoothly and evenly. It ensures continuous and uniform movement from the extrusion section.

Why It’s Important

✅ Maintains proper tension during extrusion

✅ Shapes the pipe evenly before cooling

✅ Prevents deformation and surface defects

✅ Ensures precise dimensions and a smooth finish

Result

The Farmer Take-up unit produces high-quality PVC suction hose pipes. These pipes are strong, flexible, and suitable for industrial, agricultural, and commercial use.

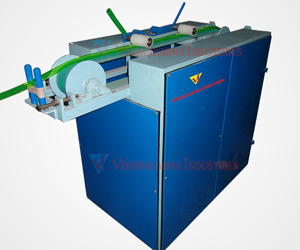

Haul-off & Coiling :

The pipe is gently pulled by a precision rubber belt haul-off unit to maintain uniform tension and avoid surface damage. It is then cut into standard lengths or wound into coils using a manual or automatic winder, ready for transport or storage.

Control Panel:

The cooled and calibrated pipe is pulled through the extrusion line using a haul-off unit. This unit maintains a consistent tension and speed to avoid any stretching or compression of the pipe. Finally, the pipe is cut to the desired length using an automated cutter. The cut pipes are then collected and inspected for quality before being packaged for distribution.

Applications of PVC Suction Hose Pipes

PVC Transparent Garden Pipes have a wide range of applications due to their versatility and durability. Here are some key sectors where these pipes are extensively used:

Our PVC suction hose pipes are widely used for: •

🚜 Agricultural water suction & delivery

🏭 Industrial liquid handling

🚚 Tanker unloading/loading pipes • 🛠 Construction site water supply • 🌾 Fertilizer and chemical transfer

These pipes are flexible. They are strong and resist abrasion. They can handle vacuum. They can also handle pressure.

EXPLORE OUR MACHINERY PRODUCTS

At Vishwakarma Industries, we manufacture and export top-grade machinery used in the plastic pipe industry, such as

Each of our machines is designed for durability, high output, low energy consumption, and minimal maintenance. Whether you’re starting a new unit or expanding capacity, we have a solution that fits your budget and technical needs.